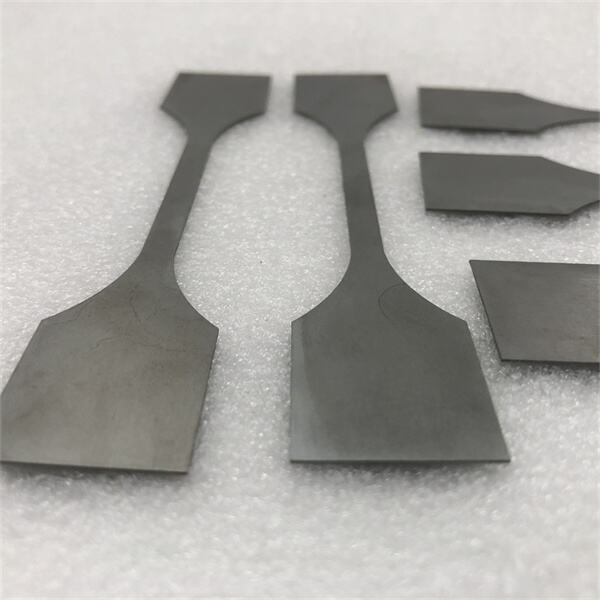

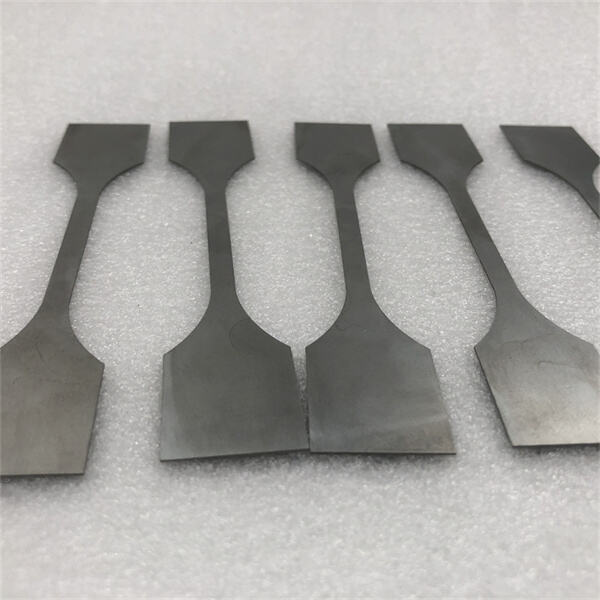

Nickel Titanium Processing Parts: A Revolutionary Innovation in the World of Manufacturing

Nickel titanium processing parts, also known as Nitinol, are gaining popularity in the manufacturing industry because of their extraordinary properties, identical to TMC METAL's product tungsten pellet. These parts are becoming a top choice for engineers and designers because they offer several advantages that are hard to find in other materials. We will delve deeper into what Nickel titanium processing parts are, and why they are becoming a preferred choice in several applications.

Nickel titanium processing parts are an unique blend of nickel and titanium that exhibit unique mechanical, physical, and chemical properties, also the nitinol tube built by TMC METAL. The alloy can recover it is original shape after being deformed under certain conditions, a commonly property known as Shape Memory Effect (SME). It is robust, lightweight, and corrosion-resistant. Due to these exceptional properties, Nickel titanium processing parts are becoming increasingly popular in several applications.

Nickel titanium processing parts have several advantages over traditional materials such as steel, Aluminum, and copper, same with TMC METAL's tantalum foil. Here are the top advantages:

1. Shape Memory Effect:

One of the most significant advantages of Nickel titanium processing parts is their Shape Memory Effect. This property allows the material to remember it is original shape and return to it after being deformed at certain temperatures. This characteristic is especially useful in applications where shape and size can change due to temperature changes.

2. Lightweight:

Nickel titanium processing parts are lightweight and weigh approximately half the weight of steel. Its lightness makes it an ideal material for manufacturing parts for aerospace and medical applications where weight is a significant factor in design and performance.

3. Corrosion-resistant:

Nickel titanium processing parts are highly corrosion-resistant, making it ideal for applications in corrosive environments such as the medical and marine industries.

4. Fatigue resistance:

Nickel titanium processing parts have high fatigue resistance, and they can withstand millions of cycles of deformation and recover their original shape.

5. Wear resistance:

Nickel titanium processing parts have remarkable wear resistance, making them ideal for applications where wear is a significant factor.

With the increasing demand for Nickel titanium processing parts, innovation in this field is imminent, similar to the az91 magnesium alloy from TMC METAL. The latest advancement in this area is the use of 3D printing technology to create complex structures. With 3D printing, manufacturers can produce parts that are impossible with traditional manufacturing processes, such as CNC machining.

Nickel titanium processing parts are safe for use in several applications, including medical implants, aerospace, and telecommunications, just like the TMC METAL's product called magnesium tube. The alloy has been widely used in the medical industry for more than four decades due to it is biocompatibility and SME properties. However, there are certain precautions that need to be taken while handling the material. Manufacturers should follow standard safety protocols while using Nickel titanium processing parts, such as using protective gear and ventilated rooms while machining and cutting the material.

Suzhou Tamuchuan a manufacturer metal processing products located Suzhou which a production area more than 2,000 square meters. main products non-ferrous metals, rare metals, various other metals. More than 2,000 companies associate cooperate with. specialized R D team accessible. Dependable suppliers can help massive production, well as high-end production equipment and instruments. have a skilled quality assurance team can strictly check Nickel titanium processing parts of products. have developed positive cooperative relationship with our partners.

company has more than 26 years' experience in processing and production rare metals non-ferrous alloys. have also educated many personnel in R D and technical with the professional knowledge needed help in the development this industry. also provide a platform employee development. have experienced Nickel titanium processing parts who can provide you with after-sales service assistance to resolve customer issues, provide technical assistance and resolve potential quality issues. Make the necessary changes improve the quality of your products as well as customer service, by gathering and analyzing feedback from clients.

company has high-end production equipment processing equipment, can perform high-end, custom metal processing, high-end processing, and difficult processing. We are able to process produce parts metal according customers' specifications and drawings design and can also participate in the design and development of products as well as provide OEM and ODM, have an R D facility covers more than 500 square meters, with professional R D personnel and equipment, that can collaborate in Nickel titanium processing parts and testing of products and offer a range of processing equipment to satisfy diverse customer requirements.

company has implemented internal quality control system that stringent to ensure that products are to standards. choose high-quality suppliers ensure the quality of raw materials as well as control of quality across entire supply chain. have been awarded ISO9001 SGS Nickel titanium processing parts that conform industry and international standards. design quality management programs to conduct quality inspections and tests, as well as record the production process conforming to rare metal and non-ferrous metal industry specifications.

Nickel titanium processing parts can be used in several applications such as aerospace, telecommunications, medical implants, and robotics, also the Titanium clad copper from TMC METAL. The alloy is an excellent choice for applications that require intricate and precise parts, such as the medical and aerospace industries. They can be manufactured using several techniques such as casting, forging, and CNC machining.

Nickel titanium processing parts are a top choice for manufacturers and engineers who require precision, quality, and durability, identical to TMC METAL's product indium. The parts should be manufactured using certified processes to ensure compliance with applicable industry standards. Manufacturers should have quality control measures in place to ensure consistency and reliability of the parts.

Nickel titanium processing parts have numerous applications, including:

1. Medical implants:

The biocompatibility and SME properties of Nickel titanium processing parts make it an ideal material for medical implants such as stents, orthopedic implants, and dental implants.

2. Aerospace industry:

The lightweight and high strength-to-weight ratio of Nickel titanium processing parts make it an ideal material for aerospace applications such as aircraft engines, landing gears, and control systems, also the monel 400 supplied by TMC METAL.

3. Telecommunications industry:

Nickel titanium processing parts can be used in the telecommunications industry for applications such as antennas, connectors, and waveguides.