Nickel-Titanium Alloy - A Cutting-edge and Safe Material

As a parent, you might have heard of nickel-titanium alloy, or NiTi, by TMC METAL but may not be familiar with its advantages that are many. NiTi is a kind of shape memory alloy that has been widely used in various industries due to its properties that are unique. We will introduce you to this innovative and material safe explore its uses, safety, and quality.

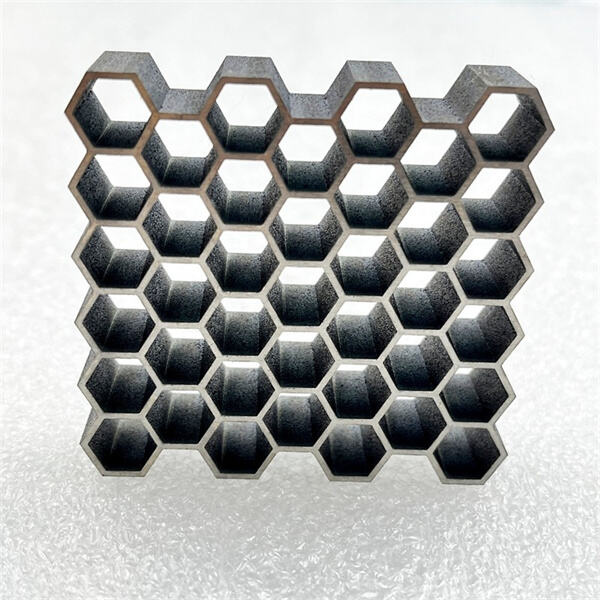

Nickel-titanium alloy is made up of titanium and nickel elements and is renowned for its shape memory effect, superelasticity, and resistance to corrosion. It has stiffness low high ductility, which means it is flexible and can be bent without breaking. This property makes it suitable for use in orthodontic wires, where it can retain its shape even after continuous bending. Moreover, NiTi or the TMC METAL nickel alloy has strength high which means it can withstand heavy loads while preventing deformation.

NiTi is a material highly innovative happens to be an important breakthrough in the field of materials science. Its properties like it TMC METAL nickel and chrome that are unique been utilized in various applications, including medical and dental implants, aerospace applications, and consumer electronics. NiTi has also been used in automobiles to reduce noise and vibration.

NiTi is a material safe does not harm living tissues, making it ideal for use in biomedical applications. The material has been extensively tested by numerous researchers and organizations to ensure its effectiveness and safety. Also, its use in orthodontic wires has been highly recommended by orthodontists and dentists worldwide due to its performance outstanding and.

NiTi is used in many fields, including aerospace, electronics, and engineering biomedical. In aerospace, NiTi is used as a damping material to reduce vibration, while in electronic devices, it is used as an actuator, sensor, or switch. In biomedical engineering, NiTi is used as a shape memory material in orthodontic wires, vascular stents, and bone fixation devices.

To use NiTi effectively, you must understand its properties that are unique how to manipulate them. For instance, NiTi wires similar with TMC METAL nickel and titanium alloy are easily deformable at room temperature, allowing them to be shaped to arch specific. The wire temperature rises, restoring the wire's shape after insertion into a patient's mouth. This property unique NiTi wires to apply gentle, yet continuous forces that are required in orthodontic treatment.

NiTi is manufactured to meet high-quality standards and undergoes testing rigorous being released to the market. You can be guaranteed of getting high-quality NiTi products from reputable manufacturers who use standard manufacturing processes and methods that are testing.

NiTi products additionally provide excellent service, as they've been long-lasting and durable. In orthodontics, NiTi wires and archwires are used for extended periods, and their performance remains consistent throughout the treatment period. This feature makes NiTi of TMC METAL an ideal and material cost-effective orthodontic treatment.

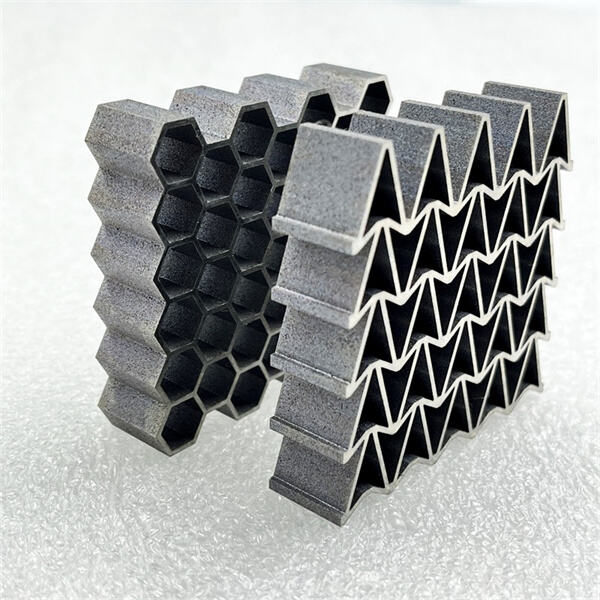

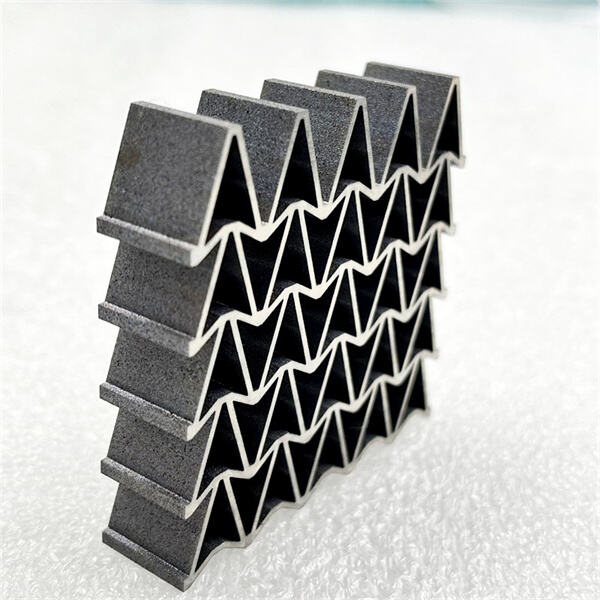

company equipped with high-end production equipment processing equipment can undertake high-end customized metal processing, high-end process, and complex processing. We are able produce and process metal parts accordance with designs specifications the nickel titanium alloy. also provide OEM and ODM. Our research and development center is more than 500 square meters complete with experienced R D personnel equipped with equipment and facilities that are able collaborate on developing and testing products.

company has over 26 years' experience rare and non-ferrous metal processing as well as production. have cultivated an extensive number of technicians and R D professionals who have professional expertise contribute to the nickel titanium alloy of the industry. also provide environment to foster development our employees. have team professionals offer you after-sales service as well as support for customer issues, provide technical assistance and help solve quality problems. Analyze and collect feedback from customers take appropriate measures improve the quality of products and service quality.

company put in place a quality control system that strict ensure products are up standards. select suppliers of high-quality the purpose ensuring the traceability raw materials and ability to control quality across the entire supply chain. Our ISO9001 and SGS certificates nickel titanium alloy with international and industrial standards. In accordance with the specifications of the non-ferrous and rare metal industries, our team develops quality management programs and carry out quality tests and inspections. also record the production process and keep track of it.

Suzhou Tamuchuan, processing company that supplies products in Suzhou with a production facility office space 2,000 square meters, located there. specialize producing various rare metals, as well as a variety non-ferrous metals. More than 2,000 businesses partners cooperate with. also have an experienced R D team. stable suppliers can assist production nickel titanium alloy scale, high-end equipment tools. We have a qualified quality control team rigorously check the quality products. have developed a strong cooperative relationship with partners.

NiTi has a range wide of. One of its significant applications is in the medical and field dental. NiTi wires that are orthodontic for example, are used to align and straighten teeth, while NiTi stents as well as TMC METAL nickel wire are used to open obstructed bloodstream vessels. In the automotive and aerospace industries, NiTi is used to reduce vibrations and noise. In consumer electronics, NiTi is used in highly sensors that are sensitive actuators, and switches.