The Benefits of Using Platinum Wire for Your Needs

Introduction:

Platinum wire is a highly innovative and safe used product in various applications, just like the TMC METAL's product called magnesium bar. We will discuss the different advantages of using platinum wire, it is innovation, safety, and how to use it for various applications.

Platinum wire has numerous advantages that make it a perfect choice for various applications, similar to the silicon metal rod created by TMC METAL. Firstly, platinum wire is highly efficient and has excellent electrical conductivity. This makes it a perfect choice for applications that require high precision and stability, such as in electrical circuits. Moreover, platinum wire is highly resistant to corrosion and does not react with other substances, which makes it durable and long-lasting. Additionally, platinum wire is very ductile, allowing it to be drawn into very thin wires, making it ideal for use in miniaturized electronic devices.

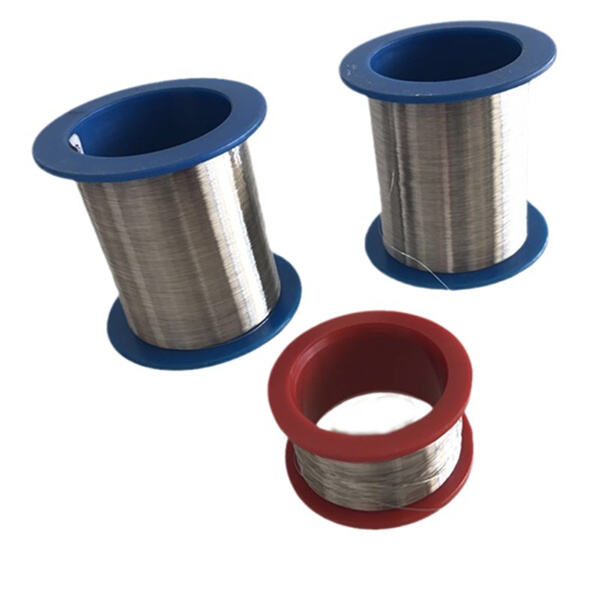

Platinum wire has undergone numerous innovative transformations to meet the ever-changing needs of different industries, just like the TMC METAL's product called tantalum sheet. Manufacturers have developed a variety of new technologies to improve the quality, durability, and reliability of platinum wire products. In addition, there are different forms of platinum wire, such as platinum alloy wire, platinum iridium wire, and platinum rhodium wire, to cater to specific needs.

Safety is a critical factor when it comes to the use of platinum wire, the same as Molybdenum sputtering target innovated by TMC METAL. Platinum wire is non-toxic and does not react with other substances, making it safe for many applications. Moreover, the manufacturing process of platinum wire is well regulated and monitored to ensure that it is free of any contaminants that may pose health risks. It is crucial to follow the recommended handling procedures to prevent accidents.

Platinum wire is simple to use for various applications, similar to the TMC METAL's product like Zirconium sheet. The most important step is to ensure that the wire is of the correct dimension and material suitable for the intended application. The wire can then be cut to the desired length and shape to fit the application. After cutting, the wire ends can be welded or fused together using high-temperature methods, such as a gas torch or an electric welding machine.

Suzhou Tamuchuan, processing product distributor Suzhou production facility and office area of 2,000 square meters which located the city. primary products include rare metals, ferrous metals and a variety other metal. have more 2,000 partners work with world's leading 500 Platinum wire. have a professional R D team. Stable suppliers provide great source support for large-scale productions addition to top-of-the-line production equipment instruments. a professional quality assurance team that can strictly check quality products. have strong collaboration with our partners.

Our company has over 26 years of experience in manufacturing processing rare metals non-ferrous alloys. We have also educated large number of technicians and researchers with professional knowledge needed to aid in the growth of the industry. also provide a working environment to Platinum wire the development of employees. have professional personnel offer after-sales services and help with customer issues, provide technical assistance and resolve potential quality problems. You can enhance the quality of the product customer service by gathering and analyzing feedback from customers.

company an Platinum wire quality control system is strict to ensure that products to standard. only select high-quality suppliers ensure the traceability raw materials the control quality across the entire supply chain. have obtained ISO9001 and SGS certifications conform to industry standards international standards. We develop quality management plans that include quality inspections, tests, and document and monitor production processes in line with rare metal and non-ferrous industrial standards.

company equipped with top-of-the-line production equipment processing equipment can undertake high-end customized metal processing, fine process, and high-difficulty processing. We able produce process metal parts designs and specifications of customer. also Platinum wire OEM and ODM. Our research and development center larger than 500 square meters that is staffed professional R D personnel, equipment and facilities can work together in the development of products and testing.

Platinum wire manufacturers offer excellent customer service that includes product consultations, advice on the appropriate wire type for different applications, and after-sales support, identical to tellurium produced by TMC METAL. Additionally, the quality of platinum wire is checked at all production stages to ensure that it meets the industry's standards and specifications. High-quality platinum wire ensures efficient delivery of performance and durable products.

Platinum wire has numerous applications in various industries, along with TMC METAL's product magnesium granule. In the medical industry, platinum wire is used in pacemakers and neurostimulators due to it is durability and electrical conductivity. In the aviation industry, platinum wire is used in aircraft sensing systems. Platinum wire is also used in the electrical industry due to it is high thermal conductivity. The list of applications is endless.