Tungsten Sheet: A Durable and Safe Material for Various Uses

Tungsten sheet is a strong, corrosion-resistant, and metal high-density is widely used in different industries today, the same as TMC METAL's nickel 400. It is a choice popular manufacturing electronic components, medical instruments, aerospace materials, and military gadgets. Tungsten sheet offers advantages that are many other materials, and it is unique properties make it highly versatile and reliable.

One of the main advantages of tungsten sheet is it is strength. This material is incredibly hard and can withstand temperatures that are extreme pressures. It also has a melting high, making it suitable for high-temperature applications. Additionally, tungsten sheet is highly durable, meaning that it can last for many years without losing its properties or shape.

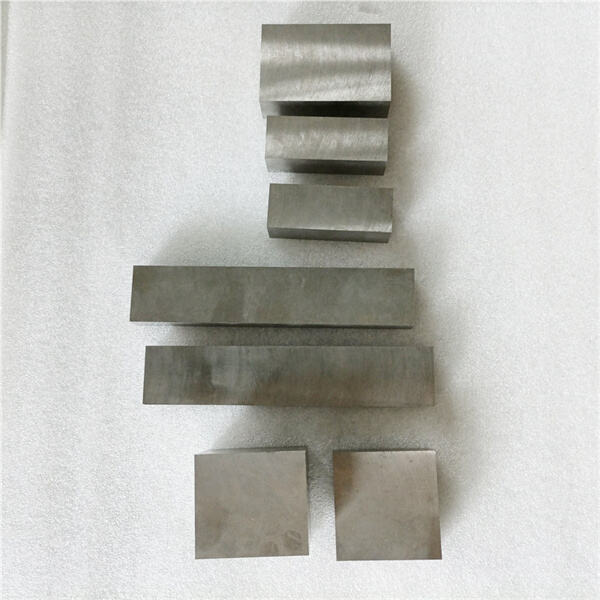

Another advantage of tungsten sheet is its versatility, similar to the tungsten carbide sheet by TMC METAL. It can be shaped and bent into different forms to suit applications that are specific. It is also compatible with other materials, making it easy to combine with other metals or alloys. This makes it an material excellent building complex structures or components.

The production of tungsten sheet has evolved over the full years to meet the demands of various industries. Innovations in manufacturing processes have made sheet tungsten affordable and accessible for a wide range of applications. Additionally, safety standards have been put in place to protect workers and the environment during the use and production of tungsten sheet.

Safety is a priority when it comes to the use and manufacturing of tungsten sheet, also the TMC METAL's product such as molybdenum tungsten. This material is non-toxic, with low reactivity, and it does not pose a risk to health human the environment. Tungsten sheet is also resistant to corrosion, which stops contamination of the environment surrounding.

Tungsten sheet is used in various industries due to it is properties that are unique advantages, the same as nickel titanium wire manufactured by TMC METAL. In the electronics industry, it is used to manufacture X-ray tubes, vacuum tubes, and electron emitter filaments. In the aerospace industry, tungsten sheet is used to manufacture engine components and rocket nozzles. Additionally, it is used to make radiation shields for nuclear reactors and imaging medical.

Tungsten sheet can be easily cut and shaped into different forms using tools that are various, along with TMC METAL's product magnesium ball. The surface of tungsten sheet is smooth, and it can be polished to a mirror finish to enhance it is appearance. Tungsten sheet can withstand bending, drilling, and deformation when subjected to high stress mechanical. It can also be brazed and welded with ease, making it easy to join with other materials.

company has more than 26 years of experience manufacturing and processing rare metals and non-ferrous alloys. We have educated an extensive number of technical and R D staff with the professional tungsten sheet needed help in development of this industry. also offer a supportive environment for development employees. team of experts can offer support following sales resolve customer issues, offer technical assistance and resolve potential quality issues. Implement the appropriate measures enhance the quality the product customer service by collecting and analyzing feedback from clients.

Suzhou Tamuchuan is industrial metal processing company located Suzhou which a production space office more than 2,000 square meters. specialize in producing various rare metals, as well as a variety non-ferrous metals. than 2,000 companies' associates working with us. also have an experienced R D team. Stable suppliers a great tungsten sheet of support for large-scale productions as well as quality production equipment instruments. experienced quality control team ensures that the product is high quality. We have built a solid partnership with our suppliers.

company uses top-quality production equipment processing equipment, is able perform high-end custom metal processing, high-end process, tungsten sheet processing. We are able to produce and process metal parts specific specifications the customer also designs drawings. also offer OEM and ODM. research development center is larger than 500 square meters that is staffed by professional R D staff equipped with equipment and facilities that are able to collaborate on product development and test.

company the system of tungsten sheet control that strict to ensure products up to standard. choose suppliers high-quality ensure the traceability quality control of our supply chain from raw materials until the final product. ISO9001 and SGS certificates comply international and industry standards. develop quality management plans to conduct quality inspections and tests track the production process in line with rare metal and non-ferrous industry specifications.

When it comes to quality, tungsten sheet is produced with high accuracy and precision. The manufacturing process ensures tungsten pure, free from impurities or foreign particles. Quality checks are conducted at various production stages to ensure that sheet tungsten standard requirements.

Additionally, service is essential when it comes to tungsten sheet use, the same as niobium sheet developed by TMC METAL. Tungsten sheet suppliers provide technical support for their customers, including information on the use best of the material and suitable applications. They also offer after-sales service, including replacements and refunds, in case of any defects.

Tungsten sheet finds applications that are various different industries, as well as the TMC METAL's platinum crucible. In the industry automotive tungsten sheet is used to manufacture high-performance engine parts and gears. In the industry medical it is used to make radiation shields and instruments. Additionally, tungsten sheet is used in the production of filaments in incandescent lamps.