Please contact us to serve you!" >

Please contact us to serve you!" >

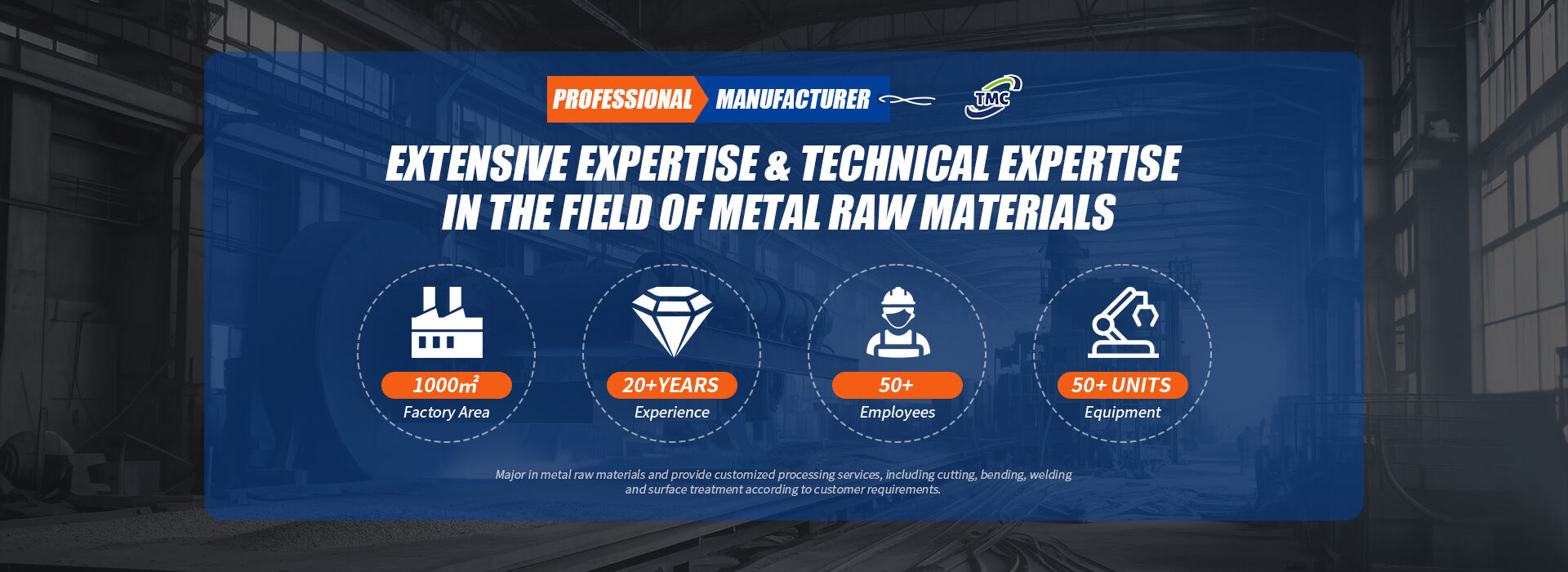

TMC METAL

Introducing the high purity tantalum rod Ta1 Ta2 RO5200 round bar for sale Tantalum Metal, provided through TMC METAL. This body excellent a suitable choice for those choosing first-class steel tantalum. It is reliable as well as resilient.

Crafted coming from the absolute best products, high purity tantalum rod Ta1 Ta2 RO5200 round bar for sale Tantalum Metal around service ideal the variety of industrial requests. The product provides you with the resilience as well as stamina you require to achieve the task no matter if you are looking for to produce machinery superior produce accuracy tools.

This tantalum steel is actually apparent of any type of pollutant that might damage its own efficiency or even resilience along with a pureness level leading. Which implies that you could depend on its own resilience as well as energy, also however in a variety of this harshest as well as very most environments that are difficult. And its own solid resistance to rust as well as oxidation assists to guarantee that it'll remain to carry out at a degree constant is higher despite prolonged use.

The high purity tantalum rod Ta1 Ta2 RO5200 round bar for sale Tantalum Metal might likewise be incredibly flexible. Its own form rounded creates ideal for a wide range of requests, while its own Sof location guarantees that it may be easily machined or even fine-tuned for your accurate specifications. This technique might be the ideal option no matter if you are looking to producing customized aspects or even just simply need a reliable assist structure.

At TMC METAL, our team are devoted towards providing high-quality products at an expense inexpensive. This is why our team are happy to source this high purity tantalum rod Ta1 Ta2 RO5200 round bar for sale Tantalum Metal in the marketplace at a cost that will not breather your allocation. Adequate factor for our quick as well as shipment reliable, you are going to become specific that the specific acquisition is provided easily and rapidly.

Variety Category |

Trademark |

Resistivity uQ·m(20℃) |

Allowable deviation |

||

Copper Nickel (Manganese) |

NC003 |

0.03 |

±10% |

||

NC005 |

0.05 |

||||

NC010 |

0.10 |

||||

NC012 |

0.12 |

||||

MC012 |

0.12 |

||||

NC015 |

0.15 |

||||

NC020 |

0.20 |

±5% |

|||

NC025 |

0.25 |

||||

NC030 |

0.30 |

||||

NC035 |

0.35 |

||||

NC040 |

0.40 |

||||

NC050 |

0.49 |

||||

nickel-chromium-iron |

NCF 072 |

0.72 |

|||

NCF 080 |

0.80 |

||||

NCF 104 |

1.04 |

||||

NCF 113 |

1.13 |

||||

Iron chromium aluminum |

FCA 126 |

1.25 |

|||

FCA 137 |

1.37 |

||||

FCA 142 |

1.42 |

||||

FCA 153 |

1.53 |

Chemical composition (mass fraction) (%) |

||||||||||||||

Trademark |

Al |

C |

Cr |

Cu |

Fe |

Mn |

Mo |

|||||||

NC003 |

margin |

|||||||||||||

NC005 |

margin |

|||||||||||||

NC010 |

margin |

|||||||||||||

NC012 |

margin |

|||||||||||||

MC012 |

margin |

3 |

||||||||||||

NC015 |

margin |

|||||||||||||

NC020 |

margin |

0.3 |

||||||||||||

NC025 |

margin |

0.5 |

||||||||||||

NC030 |

margin |

0.5 |

||||||||||||

NC035 |

margin |

1.0 |

||||||||||||

NC040 |

margin |

1.0 |

||||||||||||

NC050 |

margin |

1.0 |

||||||||||||

NCF 072 |

0.1 |

18 |

margin |

|||||||||||

NCF 080 |

3 |

margin |

||||||||||||

NCF 104 |

0.1 |

20 |

margin |

|||||||||||

NCF 113 |

0.08 |

15 |

margin |

|||||||||||

FCA 126 |

4 |

0.05 |

13 |

margin |

||||||||||

FCA 137 |

5 |

0.05 |

20 |

margin |

||||||||||

FCA 142 |

5 |

0.05 |

25 |

margin |

||||||||||

FCA 153 |

7 |

0.05 |

27 |

margin |

2 |

|||||||||

Trademark |

Resistance temperature coefficient × 10/K (20℃~600℃) |

Melting point℃ |

density g/cm3 |

Specific heat capacity J/(g·K) |

Thermal Conductivity W/(m·K) |

Linear average thermal expansion coefficient 10/K (20℃~400℃) |

Thermoelectromotive force H V/K (0℃~100℃) for copper |

NC003 |

1085 |

8.9 |

0.38 |

145 |

17.5 |

-8 |

|

NC005 |

1090 |

8.9 |

0.38 |

130 |

17.5 |

-12 |

|

NC010 |

1095 |

8.9 |

0.38 |

92 |

17.5 |

-18 |

|

NC012 |

1097 |

8.9 |

0.38 |

75 |

17.5 |

-22 |

|

MC012 |

1050 |

8.9 |

0.39 |

84 |

18 |

— |

|

NC015 |

1100 |

8.9 |

0.38 |

59 |

17.5 |

-25 |

|

NC020 |

1115 |

8.9 |

0.38 |

48 |

17.5 |

-28 |

|

NC025 |

1135 |

8.9 |

0.38 |

38 |

17.5 |

-32 |

|

NC030 |

1150 |

8.9 |

0.38 |

33 |

17.5 |

-34 |

|

NC035 |

1170 |

8.9 |

0.39 |

27 |

17 |

-37 |

|

NC040 |

0 |

1180 |

8.9 |

0.40 |

25 |

16 |

-39 |

NC050 |

-6

|

1280 |

8.9 |

0.41 |

23 |

15 |

-43 |

NCF 072 |

1425 |

7.9 |

0.12 |

13 |

— |

+3 |

|

NCF 104 |

1390 |

7.9 |

0.12 |

13 |

16 |

— |

|

NCF 113 |

1390 |

8.2 |

0.11 |

13 |

15 |

+1 |

|

FCA 126 |

15.5 |

1450 |

7.4 |

0.12 |

13 |

15.4 |

— |

FCA 137 |

8.6 |

1500 |

7.2 |

0.12 |

11 |

12 |

— |

FCA 142 |

4.1 |

1500 |

7.1 |

0.12 |

11 |

12 |

+5 |

FCA 153 |

-1.4 |

1520 |

7.1 |

0.12 |

11 |

16.6 |

— |

chemical composition,% |

||||||||

C |

S |

P |

Mn |

|||||

Synthetic grade |

Not larger than |

|||||||

6J10 |

0.05 |

0.010 |

0.010 |

≤0.30 |

||||

6J15 |

0.05 |

0.020 |

0.030 |

≤1.50 |

||||

6J20 |

0.05 |

0.010 |

0.010 |

≤0.70 |

||||

6J22 |

0.04 |

0.010 |

0.010 |

0.50~1.50 |

||||

6J23 |

0.04 |

0.010 |

0.010 |

0.50~1.50 |

||||

6J24 |

0.04 |

0.010 |

0.010 |

1.00~3.00 |

||||

chemical composition,% |

||||||||

Ni |

Cr |

Cu |

Al |

|||||

Synthetic grade |

||||||||

6J10 |

Ni+CoRemain |

9.0~10.0 |

≤0.2 |

— |

||||

6J15 |

55.0~61.0 |

15.0~18.0 |

— |

≤0.3 |

||||

6J20 |

Remain |

20.0~23.0 |

— |

≤0.3 |

||||

6J22 |

Remain |

19.0~21.5 |

— |

2.7~3.2 |

||||

6J23 |

Remain |

19.0~21.5 |

2.0~3.0 |

2.7~3.2 |

||||

6J24 |

Remain |

19.0~21.5 |

— |

2.0~3.2 |

||||