Please contact us to serve you!" >

Please contact us to serve you!" >

Product name |

Product name |

Function & Application |

Application condition |

Aluminium and titanium alloy Al-TI Alloy |

Al-Ti |

Refine the grain size of aluminium and aluminium alloy, and improve the mechanical property of materials |

720ºC put into molten aluminium |

Aluminium rare earth alloy |

Al-Re |

Improve the corrosion resistance and heat resistant strength of the alloy |

After the completion of refining, put into 730ºC molten aluminium |

Al-B alloy |

Al-B |

Remove the impurity element of electrical aluminium, and increase electric conductivity |

After the completion of refining, put into 750ºC molten aluminium |

Al-Sr alloy |

Al-Sr |

Be used for Si metamorphism and treatment of permanent mold casting, low-pressure casting or long-term casted eutectic and Improving property of castings and alloys |

After the completion of refining, put into 750ºC-760ºC molten aluminium |

Al-Zr alloy |

Al-Zr |

Refine grains and improve high-temperature strength and weldability |

|

Al-Si alloy |

Al-Si |

Be used for the addition or adjustment of Si |

Be used for the elemental addition and simultaneously putting into furnace of solid materials; the elemental adjustment is put into 710-730ºC aluminium-water, and it is just needed to stir for 10 minutes |

Al-Mn alloy |

Al-Mn |

Be used for the addition or adjustment of Mn |

Be used for the elemental addition and simultaneously putting into furnace of solid materials; the elemental adjustment is put into 710-760ºC aluminium-water, and it is just needed to stir for 10 minutes |

Al-Fe alloy |

Al-Fe |

Be used for the addition or adjustment of Fe |

Be used for the elemental addition and simultaneously putting into furnace of solid materials; the elemental adjustment is put into 720-770ºC aluminium-water, and it is just needed to stir for 10 minutes |

Al-Cu alloy |

Al-Cu |

Be used for the addition, matching or adjustment of Cu |

Be used for the elemental addition and simultaneously putting into furnace of solid materials; the elemental adjustment is put into 710-730ºC aluminium-water, and it is just needed to stir for 10 minutes |

Al-Cr alloy |

Al-Cr |

Be used for the elemental addition or composition adjustment of wrought aluminium alloy |

Be used for the elemental addition and simultaneously putting into furnace of solid materials; the elemental adjustment is put into 700-720ºC aluminium-water, and it is just needed to stir for 10 minutes |

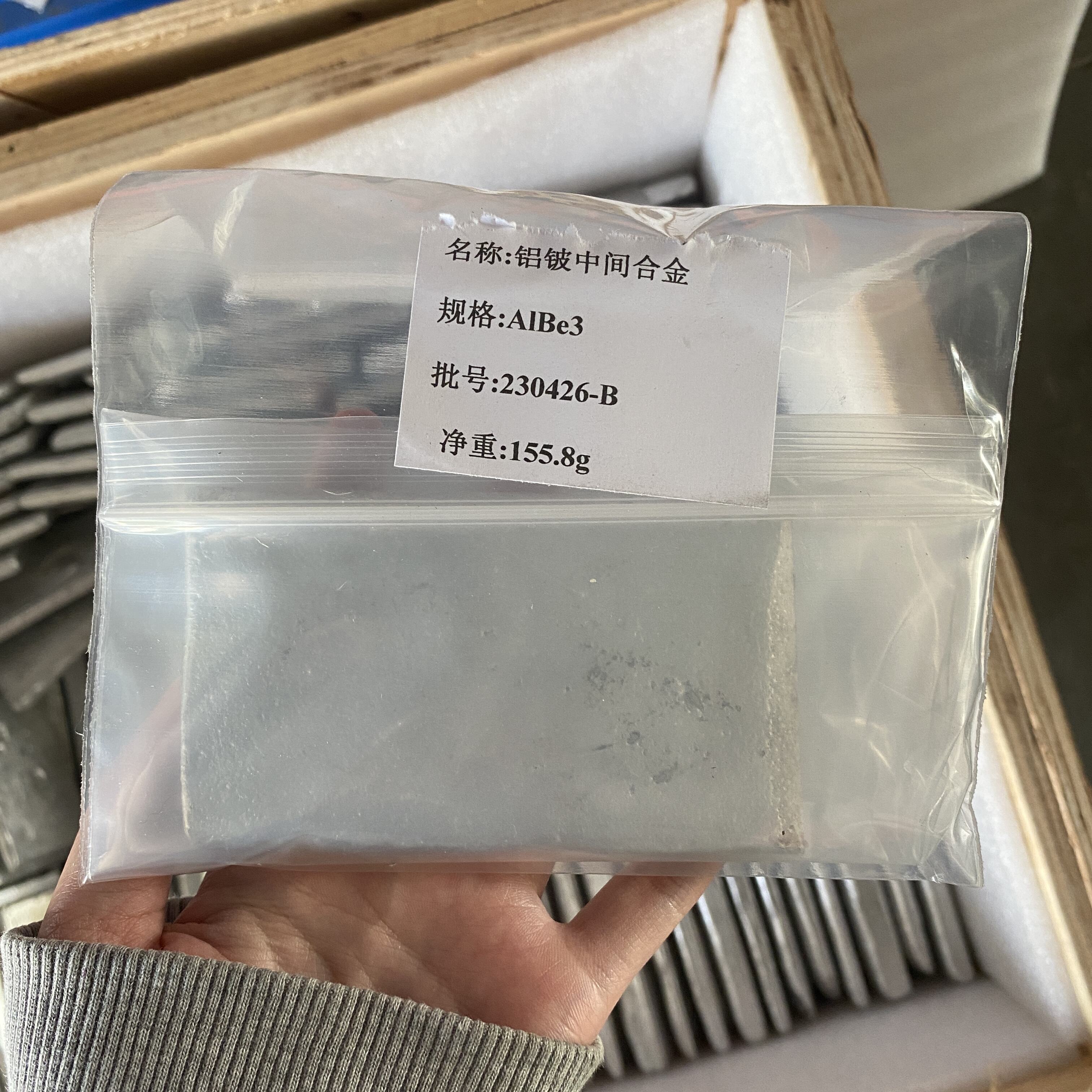

Al-Be alloy |

Al-Be |

Be used for the oxidation film filling and micronization in the process of aviation and spaceflight aluminium alloy production |

After the completion of refining, put into 690ºC-710ºC molten aluminium |

TMC METAL

The TMC METAL Raw Material Aluminum Beryllium Alloy Ingot Al-Be5% is a top-quality item that guarantees exceptional efficiency in a selection of requests. Created from premium quality lightweight aluminum and beryllium, this alloy ingot is developed to become solid and lightweight, creating it a suitable option for a variety of markets.

Well-suited to become utilized right into the aerospace, automobile, and aquatic markets, where its own higher proportion is strength-to-weight it an exceptional

choice for utilize in essential elements. An option is outstanding utilized within the building market, where its own resilience and rust protection create it a suitable item for structure products like home windows, roofing system boards, and entrances.

One connected benefit is its own excellent conductivity is thermal. This residential or commercial home enables the alloy to dissipate warm rapidly, making it a product perfect use in high-temperature requests like motor components or even home heating system and cooling down.

Offers excellent electrical conductivity along with its own thermal conductivity. This will create a choice is use in electrical aspects like circuit boards and electrical circuitry.

Remarkable machinability. This guarantees that maybe easily created and defined to meet the specific requirements of a request is specific. This creates a product that is flexible and could be utilized in a wide range of items.

Provided the appeal and need for The TMC METAL Raw Material Aluminum Beryllium Alloy Ingot Al-Be5%, it is certain to leading the listing of essential basic materials for metal-based items.