- E vreo problemă? - Nu.

Vă rugăm să ne contactaţi pentru a vă servi!

Notă |

Tensiune rezistență δbpsi (MPa), ≥ |

Rezistență la cedare δ0.2, psi (MPa),≥ |

Elongație pe o lungime de 1"/2" %, ≥ |

RO4200 -1 RO4210-2 |

18000 (125) |

12000 (85) |

25 |

Compoziție chimică % |

|||||||||

Desemnare |

Șef compoNent |

Imprurities maxim

|

|||||||

NB |

Fe |

- Da. |

Ni |

W |

Mo |

Ti |

Ta |

O |

|

Nb1 |

Restul |

0.004 |

0.003 |

0.002 |

0.004 |

0.004 |

0.002 |

0.07 |

0.015 |

Nb2 |

Restul |

0.02 |

0.02 |

0.005 |

0.02 |

0.02 |

0.005 |

0.15 |

0.03 |

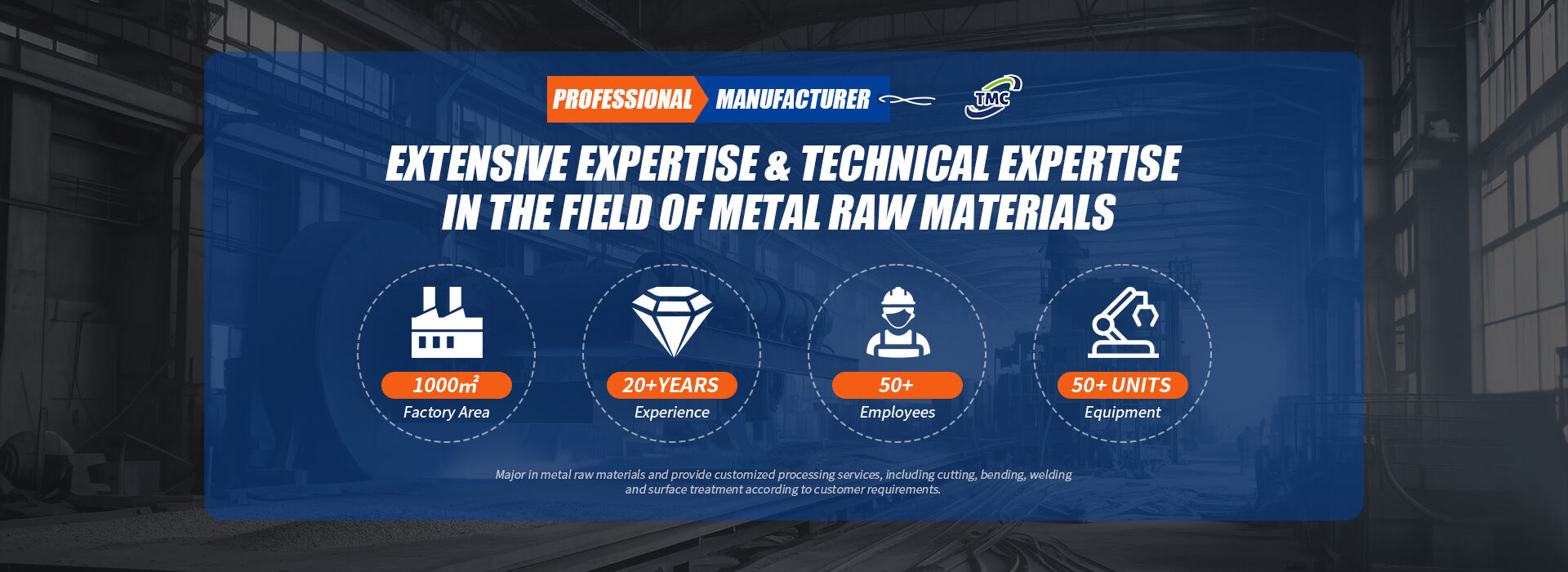

TMC METAL

Prețurile firului de sudare din aliaj superconductor niob-titan sunt în creștere și devin o opțiune de construcție populară pentru magnet. Aceste cabluri sunt fabricate folosind materiale concepute să reziste condițiilor ridicate și extreme. O marca care a reușit să se afirme ca un lider în producerea firurilor de sudare este TMC METAL.

TMC METAL utilizează doar cele mai bune materiale brute pentru a produce firul său de sudare din aliaj niob-titan. Compania se mândrește că oferă clienților săi cabluri care nu sunt doar durabile, dar și economice. Prețurile firului de sudare din aliaj superconductor niob-titan pentru magnet superconductor produse de TMC METAL pot fi utilizate pentru o gamă largă de aplicații, inclusiv producerea de magneturi superconductive.

Prețul firului de sudare din aliaj superconductor niob-titan este utilizat extensiv în multe companii diferite, inclusiv cercetare, transport și energie. Aceste magneturi sunt extrem de eficiente în generarea de zone magnetice și pot fi folosite pentru diferite scopuri, de la imaginile medicale la acceleratoarele de particule. Folosirea firului de sudare din aliaj niob-titan în producerea magnetelor s-a dovedit că este extrem de eficientă în îmbunătățirea eficienței și a satisfacției acestora.

Una dintre avantajele folosirii prețului firului de sudare din aliaj superconductor niob-titan al TMC METAL este capacitatea lor de a rezista temperaturilor ridicate adesea. Firurile au fost concepute să funcționeze la temperaturi până la 20K, făcându-le un alegere excepțională pentru aplicații în condiții extreme.

De asemenea, aceste firuri sunt fabricate prin proceduri avansate care asigură durabilitatea și longevitatea lor.

Prețul firului de sudare din aliaj superconductor niob-titaniu al TMC METAL poate fi cunoscut și pentru opoziția sa mică și abilitatea mare de a conduce curentul. Aceasta îi face o alegere perfectă pentru aplicații de magnet superconductor, acestea fiind extrem de eficiente în producerea zonelor magnetice, realizând. De asemenea, aceste fire sunt disponibile în diferite diametre, ceea ce le permite consumatorilor să folosească dimensiunea de fir care îi potrivește cel mai bine nevoile lor.

Un alt avantaj al prețului firului de sudare din aliaj superconductor niob-titaniu al TMC METAL pentru magnet superconductor este accesibilitatea acestuia. Aceste fire de sudare din aliaj superconductor niob-titaniu sunt disponibile la rate rezonabile, în ciuda construcției lor de înaltă calitate și performanței excepționale. Acest lucru le face accesibile unui larg spectru de utilizatori, inclusiv celor cu bugeturi restrânse.