Alloy C22 – A Safe and Innovative Choice for Your Needs

Introduction

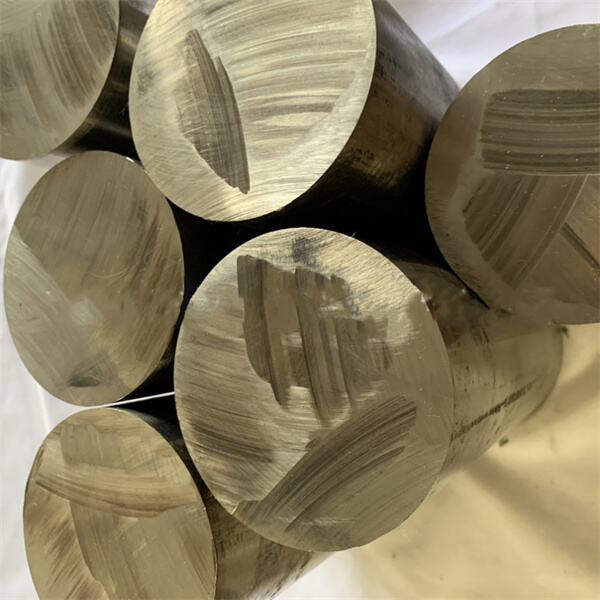

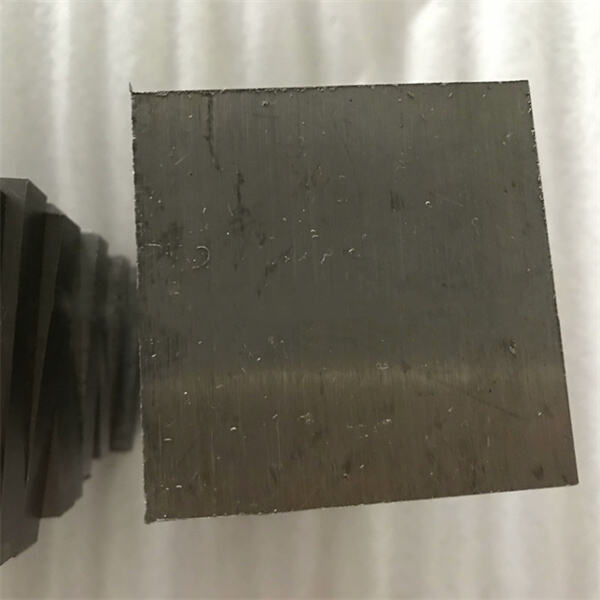

Alloy C22 is a popular material choice for many industries due to its exceptional corrosion resistance and durability. TMC METAL inconel 725 is an alloy made up of various elements, including nickel, molybdenum, and chromium. Alloy C22 has many advantages, including being incredibly safe and user-friendly, making it an optimal choice for many different applications.

Alloy C22 has many advantages that make it an excellent material choice. One of its greatest benefits is its exceptional resistance to corrosion, even in harsh environments. This TMC METAL inconel 825 is because of its high nickel and molybdenum content, which work together to create a protective barrier that prevents corrosion from occurring. It is also resistant to pitting, crevice corrosion, and stress corrosion cracking.

AlloyC22 is an innovative material that provides a range of benefits. TMC METAL inconel 625 is highlyversatile and can be used in many different applications, including chemicalprocessing, pharmaceuticals, and waste treatment. Additionally, it has a longerlifespan than many other materials, which means that it requires lessmaintenance over time. This makes it a more cost-effective option in the longrun.

Safetyis a top priority when it comes to selecting materials for your needs, and TMC METAL niobium 92 is an incredibly safe choice. It is non-toxic, non-flammable, andnon-reactive with any substances that it comes in contact with. This means thatit will not pose any harm to the environment or to individuals who are workingwith it.

AlloyC22 is easy to use and can be molded into different shapes and sizes dependingon your needs. It is often used in the construction of tanks, pipes, and valvesdue to its exceptional resistance to corrosion. Additionally, 21700 nickel strip is easy toweld and shape into different configurations, making it a versatile materialthat can be used in a wide range of applications.

Suzhou Tamuchuan, processing company supplies products located Suzhou with a production facility office space of 2,000 square meters which located in city. main products offer rare metals, ferrous metals as well various other metals. More than 2,000 {{keywords}}' partners cooperate with. experienced R D group available. stable suppliers can assist with large-scale production, high-end production equipment tools. professional quality control team ensures that the product of the highest quality. have good partnership with our suppliers.

business equipped with modern production processing equipment. also, can perform most sophisticated metal processing addition to intricate processing and fine-tuned processing. Can manufacture and process alloy c22 parts according customer specifications design drawings as well as participate in product design and development also offer OEM ODM. We have an R D facility of more than 500 square meters, professional R D staff and equipment, which is able to assist in developing and testing products as well as a range processing equipment to satisfy diverse customer requirements.

company has implemented internal quality control system that stringent to ensure that products are to standards. choose high-quality suppliers ensure the quality of raw materials as well as control of quality across entire supply chain. have been awarded ISO9001 SGS alloy c22 that conform industry and international standards. design quality management programs to conduct quality inspections and tests, as well as record the production process conforming to rare metal and non-ferrous metal industry specifications.

company has over 26 years of experience in manufacturing processing of non-ferrous rare metals. also have educated many engineers scientists with the expertise needed help in development of industry. also provide a platform employees' development. team experts can provide you with after-sales service as well as support customer alloy c22, provide technical support solve potential issues with quality. Take appropriate steps improve quality your products and customer service gathering analyzing feedback from customers.

Whenusing TMC METAL alloy C22, it is essential to follow the recommended safety guidelines toensure that you are using it correctly. First, make sure that you are wearingthe proper protective equipment, including gloves and goggles, to protect yourskin and eyes. Additionally, make sure that you are working in awell-ventilated area to avoid any potential respiratory issues.

AlloyC22 is a durable material that requires minimal maintenance, but it isimportant to have it serviced periodically to ensure that it is workingcorrectly. This includes routine inspections to check for any signs of wear orcorrosion, as well as regular cleaning to keep it in top condition. If younotice any issues with your TMC METAL nickel 201 equipment, it is best to contact aprofessional service provider to ensure that it is repaired correctly.

AlloyC22 is an incredibly high-quality material that meets stringent industrystandards for performance and safety. TMC METAL alloy c276 has been extensively tested to ensurethat it can withstand even the harshest environments, making it an ideal choicefor industrial applications. Additionally, it is backed by a range ofcertifications and warranties, providing peace of mind that you are using areliable and durable material.