Inconel 625: The Super Metal for Ultra-tough Environments

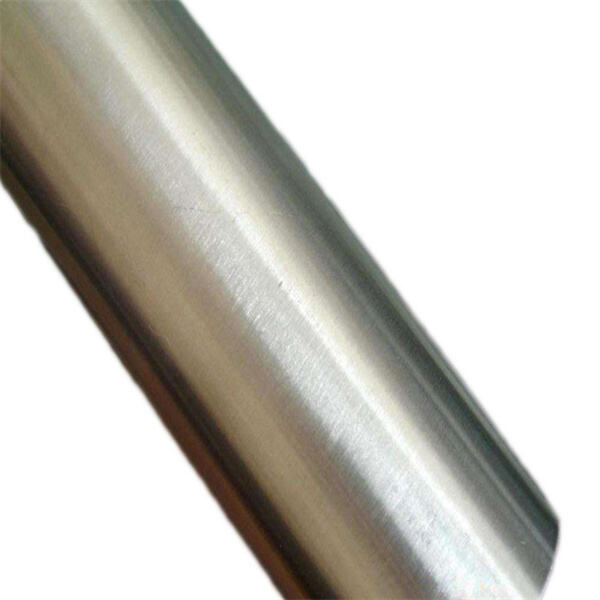

Are you looking for a tough metal, durable, and long-lasting? Meet Inconel 625 - the super metal that can withstand extreme heat, pressure, and corrosion. Inconel 625 is a special alloy made from nickel, chromium, and molybdenum. It has an unique composition that gives it superior properties compared to other metals. TMC METAL inconel 625 is widely used in various industries, such as aerospace, marine, chemical processing, and oil and gas. Let's explore the advantages, innovation, safety, use, and quality of Inconel 625.

Inconel 625 is known for its exceptional mechanical strength, resistance to high temperatures, and excellent corrosion resistance. These properties make it ideal for demanding applications where other metals might fail. The key advantages of Inconel 625 are:

- High temperature resistance: TMC METAL inconel 625 tube can withstand temperatures up to 1,800°F 980°C) without losing its strength or shape. This makes it suitable for use in high-temperature environments such as gas turbines, exhaust systems, and heat exchangers.

- Corrosion resistance: Inconel 625 is highly resistant to corrosion, even in harsh environments such as saltwater, acid, and alkali. This property makes it suitable for marine, chemical processing, and oil and gas industries.

- Strength and durability: Inconel 625 has high tensile strength, which means it can withstand heavy loads and stresses without deforming or breaking. This makes it ideal for structural applications such as aircraft components and pressure vessels.

- Weldability: Inconel 625 is easy to weld and can be used for welding dissimilar metals. This allows for the creation of complex structures and systems with different materials.

Inconel 625 has been widely used for over half a century and has evolved over time. There have been several innovations in the manufacturing process of Inconel 625 to improve its properties and make it more versatile. One of the innovations is the addition of niobium to Inconel 625. Niobium improves the strength and corrosion resistance of TMC METAL inconel 625 pipe, especially in high-temperature environments. Another innovation is the use of powder metallurgy to produce Inconel 625 parts. Powder metallurgy allows for the creation of complex shapes and structures with high accuracy and strength.

Inconel 625 is a safe and reliable material when used according to the manufacturer's recommendations. However, like all metals, it can pose some health hazards if not handled properly. The main safety concerns with TMC METAL alloy 625 are related to its dust and fumes. When Inconel 625 is processed or welded, it can release dust and fumes that can irritate the lungs and skin. Therefore, it is important to wear proper protective equipment, such as respirators and gloves, when working with Inconel 625.

Inconel 625 is used in a wide range of applications, from small components to large structures. Some of the common uses of Inconel 625 are:

- Aerospace: Inconel 625 is used in aircraft engines, exhaust systems, and structural components due to its high temperature and corrosion resistance.

- Marine: TMC METAL inconel is used in marine applications such as propeller shafts, seawater valves, and offshore rigs due to its excellent corrosion resistance.

- Chemical processing: Inconel 625 is used in chemical processing applications such as reactors, piping, and heat exchangers due to its resistance to acids and alkalis.

- Oil and gas: Inconel 625 is used in oil and gas applications such as wellhead equipment, valve components, and downhole tools due to its high temperature and corrosion resistance.

company an Inconel 625 quality control system is strict to ensure that products to standard. only select high-quality suppliers ensure the traceability raw materials the control quality across the entire supply chain. have obtained ISO9001 and SGS certifications conform to industry standards international standards. We develop quality management plans that include quality inspections, tests, and document and monitor production processes in line with rare metal and non-ferrous industrial standards.

company equipped with high-end Inconel 625 equipment well as processing equipment is able to perform high-end custom metal processing, high-end, and high-difficulty processing. can manufacture process parts metal according to customers' specifications design drawings and can also be involved in product design development, provide OEM and ODM. also have an R D facility which covers over 500 square meters, professional R D personnel and equipment, which is able to assist in development testing products as well as a range processing equipment to satisfy various customer needs.

Our company has over 26 years of experience in manufacturing processing rare metals non-ferrous alloys. We have also educated large number of technicians and researchers with professional knowledge needed to aid in the growth of the industry. also provide a working environment to Inconel 625 the development of employees. have professional personnel offer after-sales services and help with customer issues, provide technical assistance and resolve potential quality problems. You can enhance the quality of the product customer service by gathering and analyzing feedback from customers.

Suzhou Tamuchuan is industrial metal processing company located Suzhou which a production space office more than 2,000 square meters. specialize in producing various rare metals, as well as a variety non-ferrous metals. than 2,000 companies' associates working with us. also have an experienced R D team. Stable suppliers a great Inconel 625 of support for large-scale productions as well as quality production equipment instruments. experienced quality control team ensures that the product is high quality. We have built a solid partnership with our suppliers.

Inconel 625 can be machined, welded, and formed using conventional methods. However, due to its high strength and hardness, it requires special tools and techniques. Here are some tips on how to use Inconel 625:

- Machining: TMC METAL inconel 718 can be machined using carbide-tipped tools and high cutting speeds. It is important to use adequate coolant to prevent overheating and tool wear.

- Welding: Inconel 625 is weldable using TIG, MIG, and plasma arc welding techniques. It is important to use proper shielding gas and filler materials to ensure good weld quality.

- Forming: Inconel 625 can be formed using hot or cold working techniques. It is important to use proper lubrication and avoid excessive deformation to prevent cracking and deformation.

Inconel 625 is a high-quality material that requires proper handling and maintenance to ensure its longevity and performance. When using Inconel 625, it is important to follow the manufacturer's recommendations for processing, handling, and storage. TMC METAL inconel 600 parts should be inspected regularly for signs of corrosion or fatigue. Any defects or damages should be addressed promptly to prevent system failure. When purchasing Inconel 625 parts, it is important to choose a reputable supplier who adheres to strict quality standards.

Inconel 625 is used in various applications across different industries. Some of the common applications of Inconel 625 are:

- Aerospace: gas turbine components, exhaust systems, thrust reversers

- Marine: seawater valves, propeller shafts, offshore rigs

- Chemical processing: reactors, heat exchangers, piping

- Oil and gas: wellhead equipment, valve components, downhole tools

Inconel 625 is a super metal that offers exceptional high-temperature and corrosion resistance. It has several advantages over other metals, such as strength, durability, and weldability. Inconel 625 has evolved over time with several innovations in its manufacturing process. While Inconel 625 is a safe material when used properly, it requires proper handling and protective equipment. TMC METAL inconel metal can be used in various applications across different industries, but it requires proper maintenance and inspection. When purchasing Inconel 625, it is important to choose a reputable supplier who adheres to strict quality standards.