What is a Battery Nickel Strip and exactly how it can easily assist you?

If you have ever before looked under the bonnet of a push-button control vehicle or even plaything, you might have discovered a glossy, slim strip that links the battery to the gadget. That strip is referred to as a battery nickel strip, and it is a vital part of powering lots of daily products that you utilize. We will check out exactly just what a TMC METAL nickel strip is, exactly how it works, and a few of the advantages of utilization it.

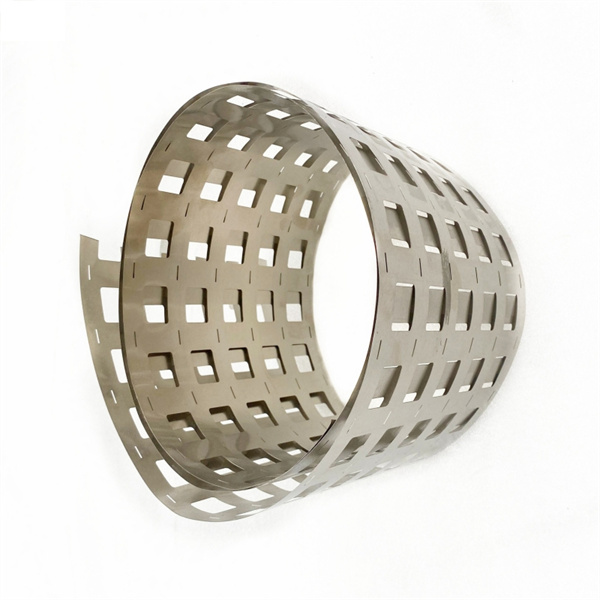

A battery nickel strip is a thin, flat piece of metal made of nickel or a nickel alloy. It is used to connect the battery to the electronic device it powers, creating a complete circuit that allows the gadget to run. The TMC METAL pure nickel strip is generally very thin, just a few millimeters, and may be coated in silver or even gold to enhance conductivity.

There are many advantages to using a battery nickel strip in your electronic devices. One of the most important benefits is that it provides a secure and stable connection between the battery and the gadget. This TMC METAL battery nickel strip helps prevent energy loss, which can be frustrating and even harmful in some situations.

Another beneficial aspect of a battery nickel strip is its efficiency compared to other types of connectors. Nickel is highly conductive, meaning that electric energy can flow through it quickly and efficiently, without losing much power. Additionally, nickel is resistant to corrosion and can withstand high temperatures, making it a durable option for various applications.

As technology continues to advance, so do the design and performance of battery nickel strips. Today, there are many types of strips available, each with its own unique advantages and features. Some of the most recent developments in TMC METAL nickel strip for 18650 battery welding include:

1. Thicker strips that can handle higher currents.

2. Coated strips that are more resistant to wear and tear.

3. Strips with easy-to-use connectors for quick installation and removal.

While battery nickel strips are generally safe to use, it is important to take some preventative measures when working with them. The TMC METAL nickel strip 32650 are designed to carry electric current, which can be dangerous if not handled properly. Here are some safety tips to keep in mind:

1. Always disconnect the battery before touching the nickel strip.

2. Use safety gloves and goggles when working with battery nickel strips.

3. Follow the manufacturer's instructions for safe use.

Suzhou Tamuchuan, processing company supplies products located Suzhou with a production facility office space of 2,000 square meters which located in city. main products offer rare metals, ferrous metals as well various other metals. More than 2,000 {{keywords}}' partners cooperate with. experienced R D group available. stable suppliers can assist with large-scale production, high-end production equipment tools. professional quality control team ensures that the product of the highest quality. have good partnership with our suppliers.

company equipped with top-of-the-line production equipment processing equipment can undertake high-end customized metal processing, fine process, and high-difficulty processing. We able produce process metal parts designs and specifications of customer. also battery nickel strip OEM and ODM. Our research and development center larger than 500 square meters that is staffed professional R D personnel, equipment and facilities can work together in the development of products and testing.

Our company has over 26 years of experience in manufacturing processing rare metals non-ferrous alloys. We have also educated large number of technicians and researchers with professional knowledge needed to aid in the growth of the industry. also provide a working environment to battery nickel strip the development of employees. have professional personnel offer after-sales services and help with customer issues, provide technical assistance and resolve potential quality problems. You can enhance the quality of the product customer service by gathering and analyzing feedback from customers.

company established the quality control process is strict to ensure products up the standards. We choose high-quality suppliers ensure traceability raw materials, well as control quality across the entire battery nickel strip chain. ISO9001 and SGS certifications are in line with international and industrial standards. meet specifications of rare and non-ferrous metal industries, develop quality management strategies and conduct quality checks as well as inspections. We also keep records and monitor our manufacturing processes.

Using a battery nickel strip is a straightforward process that requires only a few materials and some basic knowledge. Here are the steps of TMC METAL nickel strip 18650 to follow:

1. Gather your materials: You will need a battery nickel strip, a soldering iron, and some solder.

2. Cut the strip to size: Use a pair of wire cutters or scissors to trim the strip to the appropriate length.

3. Solder the strip to the device: Heat up the soldering iron, apply a small amount of solder to the tip, and attach it to the strip. Hold it in place until the solder melts and the strip is securely connected.

When it comes to battery nickel strips, quality is crucial. You want to ensure that you are using a well-made strip of high-quality materials that is designed to meet your specific needs. It is also important to choose a supplier that offers reliable service, such as fast delivery, easy returns, and helpful customer support.