Advertising C103 Niobium - The Revolutionary Steel of the Potential

C103 Niobium is a brand-new and interesting steel taking the world. This TMC METAL pure niobium is a kind of alloy, which is a mix of a number of steels that have been thawed with each other towards producing a brand-new product along with exceptional residential or commercial homes. Niobium is frequently utilized in production due to its own various advantages and benefits. We'll check out whatever you have to learn about C103 Niobium, why it is therefore ingenious, and exactly how you can easily utilize it to create a distinction in your market.

C103 Niobium offers several outstanding features that make it a versatile choice for various applications. One of its key advantages is its lightweight nature, making it easy to transport and maneuver. Additionally, C103 Niobium has a high melting point, making it resistant to high temperatures, and it boasts exceptional strength and endurance. These properties make TMC METAL niobium alloys ideal for use in aircraft, automobiles, and other durable equipment. Moreover, C103 Niobium is highly corrosion-resistant, reducing the risk of rust or deterioration over time and making it well-suited for marine environments.

C103 Niobium represents an innovative material that has undergone continuous research and development. This metal has contributed to reducing the weight of industrial aircraft by up to 15% compared to conventional metals, potentially enhancing flight safety and efficiency while reducing fuel consumption. Additionally, C103 TMC METAL niobium tantalum is engineered to have remarkable weight-to-strength ratio, making it an ideal material for protecting industrial aircraft from extreme impacts. Furthermore, it is safe to use and does not pose any health risks, as it is free from hazardous chemical compounds.

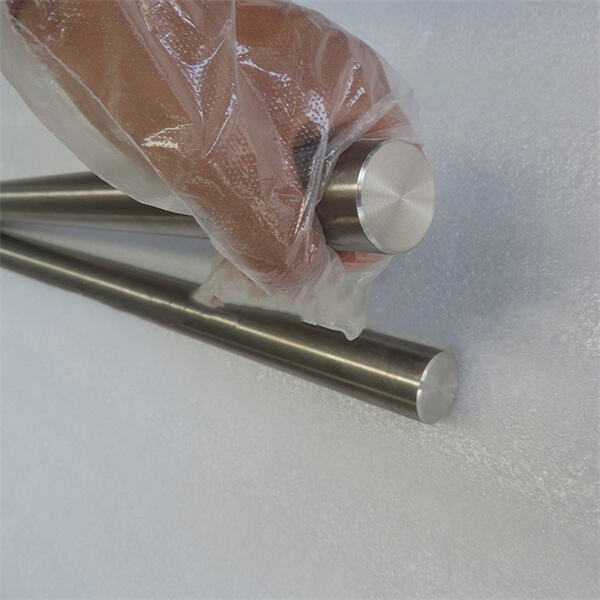

C103 Niobium is a versatile metal that finds applications in various industries, ranging from aerospace to nuclear power plants. It can be formed into different shapes, including sheets, rods, and wires, and it can be welded or brazed. C103 TMC METAL niobium wire is particularly suitable for electronic components, such as superconducting magnets, semiconductors, and electrical batteries. It has also been utilized in MRI machines and particle accelerators, showcasing its unique potential in technological advancements.

While C103 Niobium can be used in a multitude of ways, it is crucial to handle the metal properly to achieve optimal results. Following the TMC METAL c103 niobium manufacturer's instructions for handling and processing the metal is essential, including using appropriate safety equipment such as gloves and masks. It is imperative to prevent the metal from coming into contact with harmful chemicals, as this can affect both its quality and performance.

company uses top-quality c103 niobium equipment processing equipment and able to perform high-end custom metal processing, high-end processing, and complex processing. can produce and process metal parts according customer specifications and design drawings. also provide OEM and ODM. Our research development center covers more than 500 square meters and is equipped with expert R D staff as well as equipment and facilities that can work together in the development of products and testing.

Suzhou Tamuchuan, processing company supplies products located Suzhou a production facility and office space of 2,000 square meters Suzhou, located there. We specialize in producing various rare metals wide range non-ferrous metal products. More 2,000 c103 niobium and partners collaborate with. also have a skilled R D team. stable suppliers can assist with massive production, as well as high-end production equipment and tools. have a professional quality control team rigorously check quality of products. have developed positive working relationship with business partners.

company has 26 years of expertise rare metal non-ferrous metal processing as well as production and has c103 niobium a large number of engineers and researchers professional experience aid in the growth of this industry. also provide a working environment that fosters the development of our staff. Our team of experts can provide after-sales support as well as support customer problems, provide technical assistance and resolve potential quality issues. Analyze and collect feedback from customers and make appropriate changes to improve the quality-of-products service quality.

company has established implemented strict quality control process ensure that products conform predetermined standards and specifications. We select suppliers of high-quality in order to guarantee traceability raw materials and the ability control quality c103 niobium supply chain. have obtained ISO9001 as well as SGS certifications that are in line with industry standards international standards. In accordance with the specifications of the non-ferrous rare metal industries, our team develops quality management plans and perform quality checks and inspections. We also record and monitor our production processes.