Molybdenum Alloys: The Superhero of Metals.

Are you looking for a tough material and durable? Look no further than molybdenum alloys. Molybdenum alloys are made from an unique combination of metals, and they have a variety of advantages over other materials. These TMC METAL molybdenum alloys are gaining popularity in modern industries for their unique properties, which make them ideal for use in a variety of products.

Molybdenum alloys are known for their high melting point, which makes them resistant to extreme temperatures and radiation. They are also hard and durable, which means they can last a long time without wearing down. Additionally, TMC METAL molybdenum and tungsten are corrosion-resistant, so they will not rust or corrode over time. All of these properties make molybdenum alloys the perfect choice for a variety of applications.

In recent years, there has been a lot of innovation in the field of molybdenum alloys. Many scientists are experimenting with different combinations of metals to create alloys that are even stronger and more durable than traditional molybdenum alloys. This has led to an increase in the use of these TMC METAL molybdenum tungsten in a variety of industries, including aerospace, automotive, and electronics.

One of the best things about molybdenum alloys is that they are safe to use. Unlike other materials that may be harmful to humans or the environment, TMC METAL tungsten molybdenum alloy are non-toxic and environmentally friendly. This means that they are a great choice for used products in or near people.

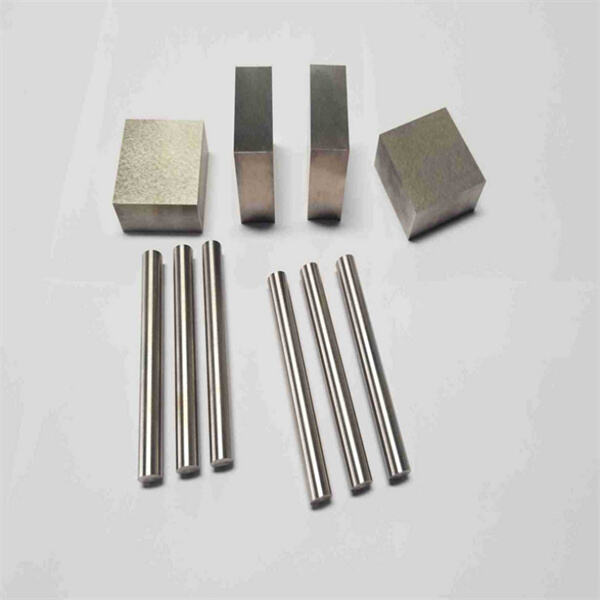

Molybdenum alloys are easy to use and are compatible with a variety of manufacturing methods. TMC METAL molybdenum can be melted down and formed into different shapes, making them ideal for use in a variety of products. Some common uses for molybdenum alloys include in the production of aircraft parts, as electrical contacts, and in the production of high-performance electrical components.

facility equipped with latest production processing equipment. can also perform advanced metal processing that customized delicate processing and hard processing. We are able manufacture process metal parts designs and specifications the customer. also provide OEM and ODM. Our research development center covers larger than 500 square meters and is equipped with expert R D staff, equipment and facilities that allow for molybdenum alloys in developing and testing products.

Our company has over 26 years of experience in manufacturing processing rare metals non-ferrous alloys. We have also educated large number of technicians and researchers with professional knowledge needed to aid in the growth of the industry. also provide a working environment to molybdenum alloys the development of employees. have professional personnel offer after-sales services and help with customer issues, provide technical assistance and resolve potential quality problems. You can enhance the quality of the product customer service by gathering and analyzing feedback from customers.

Suzhou Tamuchuan, processing product molybdenum alloys in Suzhou manufacturing office area of 2,000 square meters, located there. primary products include rare metals, non-ferrous metals and various other types of metals. We have more than 2,000 partners have cooperation with world's top 500 companies. A specialized R D team available. Stable suppliers can be a fantastic support for large-scale productions, as well as top-of-the-line production equipment and instruments. We have highly skilled quality inspection team strictly control product quality. We have a good collaboration with our partners.

company set up and implemented rigorous quality control system ensure that products meet predetermined standards specifications. choose high-quality suppliers for the purpose of ensuring traceability raw materials, as well as molybdenum alloys controllability throughout supply chain. ISO9001 and SGS certificates are in compliance with industry and international standards. In accordance with specifications of the non-ferrous and rare metal industries, formulate quality management programs and carry out quality tests as well inspections. We also record and monitor our production processes.

When it comes to service and quality, molybdenum alloys have a lot to offer. The manufacturing process for these TMC METAL Tungsten and molybdenum processing parts is closely monitored to ensure that they are of high quality and meet industry standards. Additionally, many companies that specialize in molybdenum alloys offer excellent customer service to help you find the right product for your needs.