Cobalt-chromium-molybdenum alloys (CoCrMo alloys) are a type of metallic alloy made from three metal elements: cobalt, chromium, and molybdenum. These metals by TMC METAL when alloyed (combined) react with each other and form alloys which have specific very properties useful in a lot of areas. So, now, let us look at some amazing uses of these alloys in our lives now.

Great for Medical Implants

Medical applications are one of the most important uses of cobalt-chromium-molybdenum alloys, particularly in relation to medical implants. Medical implants are products that are meant to go in your body and help people. All of these alloys have high tensile strength, so they resist extensive pressure and stress. This makes them ideal materials for manufacturing artificial joints — like hips and knees and dental implants that help individuals who have lost their teeth. These alloys have an additional wonderful advantage, that they don't rust; they don't turn rot and that makes them risk-free to use in the human body without creating injury. This is critically important because we want to guarantee that anything that enters our bodies is safe and durable.

Helping Airplanes and Rockets

In the aerospace industry, scientists and engineers design and build planes and rocket, and cobalt-chromium-molybdenum alloys help improve performance. These alloys remain extremely lightweight, enabling an overall reduction in the total weight of planes and rockets. A lighter airplane flies more efficiently, which saves fuel and makes flying more affordable. These alloys are also extremely strong, vital to endure the intimidation forces that accompany takeoff and landing. The rigor of these materials is critical to ensuring that airplanes and rockets can operate safely even in extreme conditions.

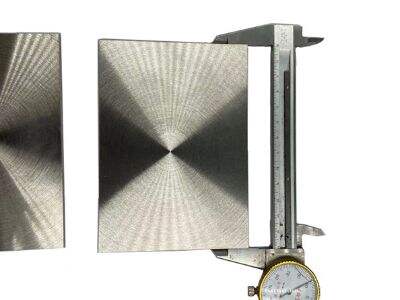

More Powerful Machines for Industrial Floors

Cobalt-chromium-molybdenum alloys improve the durability of the machines that work particularly hard in factories to produce products. These are very solid alloys, resistant to millage. This means machines made with these alloys can work uninterrupted for extended periods without repairs or replacements. In manufacturing, wearing and tearing machines are not an option, because it hampers the whole production process. When machines last longer, businesses are saving money and time because they don’t have to be repaired or replaced as often.

Resistant to Rust in Water

However, areas that have a lot of water, whether in oceans, rivers, or lakes, can allow metal items to quickly rust. This is due to metal corroding when water comes in contact with it. Cobalt-chromium-molybdenum alloys are used in water-containing environments because they resist rust. As a result, anything made out of these alloys will remain unspoiled for a long time. Boat propellers, underwater pipes, and other equipment used in marine activities are dominantly made for the fact. Utilizing these alloys allows us to make sure critical infrastructure and implements that come into contact with water will remain safe and operable long after their benches are put into active service.