Procesul de producție al produselor metalice finalizate este adesea complex și trece, de regulă, prin mai multe etape. Procesoarea diferitelor metale prin procedee variate necesită mașini și echipamente diferite, motiv pentru care este de asemenea foarte important să se determine procesul de producție.

În continuare, vom prezenta tehnologia de producție existentă a companiei noastre și echipamentele de prelucrare care vor fi dezvoltate treptat în viitor;

În prezent, compania noastră deține 11 linii de producție profesionale (pregătire materiale-prelucrare-montaj-inspecție calitate și control-tratare deșeuri-ambalare și expediere), 4 laboratoare de control calitate, peste 10 dispozitive de control calitate, peste 80 de unități de prelucrare Taiwan, peste 50 de tehnicieni profesioniști și personal de control calitate.

1. Zona de pregătire a materialelor:

Pregătiți materialele necesare și utilizați macheta și măcinătoarea pentru a fractura și a reduce în pudră. Materialele brute fractureate sunt apoi topite sau flotate pentru a separa impuritățile. După extracția metalului, acesta este purificat și rafinat pentru a elimina impuritățile reziduale și purificat ulterior, ceea ce poate fi realizat prin distilare chimică, electroliză, etc. În cazul aliajelor, aliajele sunt pregătite cu alte metale pentru a schimba proprietățile și utilizările lor, ceea ce implică amestecarea cu alte metale, topirea și răcirea, etc.

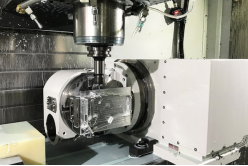

2. Zona echipamentelor de prelucrare:

Această zonă de echipamente include mașini CNC, presuri, tăietoare, mașini de ognit, tornuri, fraze și alte echipamente. Este folosită în principal pentru prelucrarea, tăierea, perforarea, estampajul, tăierea și alte operațiuni de prelucrare a materialelor metalice pentru a satisface diferitele nevoi ale clientilor. De asemenea, există echipamente de tratament superficial, cum ar fi sprăjurile, electroplatarea, polirea, oxidația și alte echipamente și zone de proces, pentru a trata suprafețele produselor după cerere.

3. Zona de montaj:

Dacă piesele fabricate trebuie instalate, acestea vor fi montate uniform în zona de montaj. La acest punct, întregul produs este finalizat și poate trece la următoarea etapă.

4. Zona de inspecție și control calitativ:

Piesele metalice sau profilurile metalice fabricate și asamblate trebuie să fie supuse inspecțiilor de calitate pe loturi sau inspecțiilor aleatoare în departamentul de control calitativ, conform cerințelor clientului și complexității produsului. Pentru profilele de inaltă puritate sau aleiate, se pot folosi pași, micrometre, metrii, gauge-uri de adâncime etc., pentru a măsura dimensiunile produselor: adâncime, diametru, lungime etc. Componentele sau piesele mici pot fi testate cu precizie și inspectate din punct de vedere al calității folosind microsoabe, raze X, ultrasonic, instrumente de testare a presiunii și a duretății, echipamente de analiză chimică, măsurătoare de rugositate a suprafeței, echipamente de testare a rezistenței și alte instrumente.

5. Zona de ambalare și expediție:

Dacă produsele inspectate respectă standardele de expediere și cerințele clientului, acestea pot fi plasate în zona de ambalare și expediere. Angajații magazinului vor alege o ambalajă adecvată pentru a ambala produsele în mod uniform, le vor marca și le vor clasifica pentru expediere.