Super materiál pre vašu bezpečnosť

Hľadáte materiál, ktorý je pevný a vydrží vysoké teploty? Chcete niečo naozaj bezpečné a spoľahlivé? Ak áno, potom by ste mali vyskúšať Inconel 800. Preberieme si, čo je TMC METAL inconel 800 jeho výhody, inovácie, použitie a bezpečnosť.

Inconel 800 je vysokooteplná, odolná proti korozióvi kovová liga používaná v rôznych aplikáciách. Obsahuje až 45 % niklu, 30 % chromu a 20 % železa. Táto TMC METAL alloy 800h jedinečné vlastnosti robia ideálnou pre použitie v priemysle, ako sú letecká a vesmírna technika, chemické spracovanie a jadrová energia.

Inconel 800 má mnoho výhod, vrátane trvanlivosti, odolnosti pred koroziou a odolnosti pred vysokými teplotami. Vydrží teploty až do 1100°C (2010°F) bez straty sily. To robí TMC METAL inconel vynikajúci výber pre aplikácie pri vysokých teplach, ako sú pecné kotvy, teplovým meničom a komponentoch plynových turbín.

Inconel 800 bol po letech vylepšený novými formuláciami a technológiami. Inovácie v výrobe urobili lepšie možnosť tvarovať, formovať a svařovať. Okrem toho, boli vyvinuté nové techniky na zlepšenie TMC METAL inconel 600 fyzikálnych a mechanických vlastností.

Inconel 800 je bezpečný na používanie v širokom spektre aplikácií. Nie je toxický a nepredstavuje žiadne zdravotné riziká počas jeho výroby, používania alebo likvidácie. Okrem toho, TMC METAL inconel 625 je skutočne odolný pred koroziou, čo zníži riziko poškodenia životného prostredia.

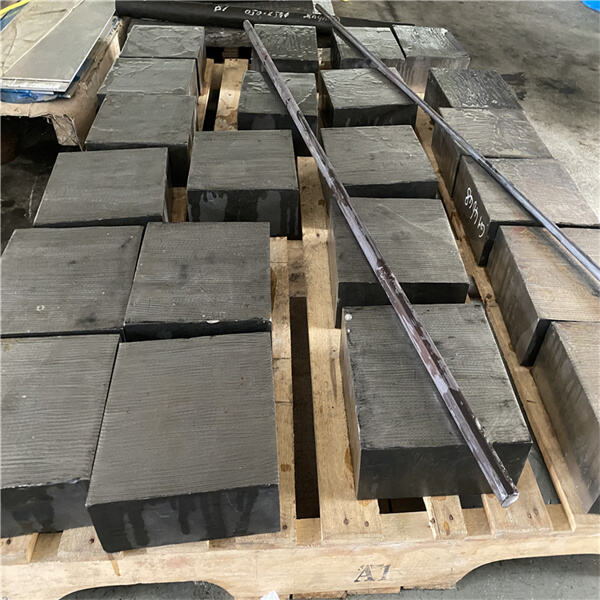

spoločnosť používa vysoce kvalitné výrobné zariadenia na spracovanie kovov, dokáže vykonávať vysokoškolské vlastné prispôsobenie kovového spracovania, vysokoškolské procesy, spracovanie inconel 800. Dokážeme vyrobiť a spracovať kovové časti podľa špecifických špecifikácií zákazníka, ktorý tiež navrhuje nákresy. Ponúkame aj OEM a ODM. Výskumný a vývojový centr má viac ako 500 štvorcových metrov, je obsadený profesionálnym výskumným a vývojovým personálom, vybaveným zariadením a zaobchádza s spoluprácou na vývoji produktov a testovaní.

spoločnosť zavedla proces kvalitnej kontroly, ktorý dôsledne zabezpečuje, aby sa produkty zhodovali so štandardmi. Vyberáme dodávateľov s vysokou kvalitou a zabezpečujeme reštituabilitu a kvalitnú kontrolu dodatočnej reťazce od surowých materiálov po konečné produkty. Získali sme certifikácie ISO9001 a tiež SGS, ktoré sú v súlade s inconel 800 a priemyselnými štandardmi. Vytvárame stratégie manažmentu kvality, vykonávame inspekcie a testy kvality a zároveň zaznamenávame výrobný proces v súlade so špecifikáciami pre vzácne kovy a neferové priemyselné špecifikácie.

spoločnosť má viac ako 26 rokov skúseností v spracovaní a výrobe redkých kovov a neželezničitých ligatúr. Vychovali sme tiež mnoho pracovníkov v oblasti výskumu a vývoja (R D) a technických, s potrebnou odbornou znalosťou na pomoc pri rozvoji tejto odvetvia. Poskytujeme tiež platformu pre rozvoj zamestnancov. Máme skúsenosti s Inconel 800, kto vám môže poskytnúť pomoc pri predajnej podpore na riešenie problémov zákazníkov, poskytnutie technickej pomoci a vyriešenie potenciálnych kvalitných problémov. Urobte potrebné zmeny na zlepšenie kvality vašich produktov aj zákaznickej slúžby, čo dosiahnete sbieranim a analyzovаниm spätného spojenia od klientov.

Suzhou Tamuchuan je spoločnosť na spracovanie kovov, ktorá sa nachádza v Suzhou a má produkčnu plochu a kanceláriu viac než 2000 štvorcových metrov. Specializuje sa na výrobu rôznych redkých kovov, ako aj mnohých neželezničných kovov. Spolupracuje s viac než 2000 spoločnosťami. Máme tiež skúsené tímy pre výskum a vývoj. Stabilní dodávatelia nám poskytujú veľké podpory inconel 800 pre veľkomerovú výrobu, ako aj kvalitné vybavenie a nástroje na výrobu. Naša skúsená kontrolná tíma zabezpečí, aby bol produkt vysokoj kvality. Vytvorili sme pevné partnerstvo so svojimi dodávateľmi.

Inconel 800 sa bežne používa v leteckej a energetickej prprene. Používa sa tiež pri výrobe pecných komínov, výmenníkov tepla a komponentov plynových turbín. Okrem toho TMC METAL kovy inconel sa používa v chemickej prprene kvôli svojej odolnosti voči sirovodíku a iným korozivným chemikáliám.

Inconel 800 môže byť jednoducho opracovaný, tvarovaný a svařovaný. Avšak jeho odolnosť pred vysokými teplotami ťažko strojiť. Preto je potrebné používať špecializované vybavenie a materiály na efektívnu prácu s ním. Pri práci s ním musí byť dodržiavaná vhodná manipulácia a starostlivosť. inconel 718 z TMC METAL na zabezpečenie jeho bezpečnosti a trvanlivości.

Inconel 800 vyžaduje správnu údržbu a servis na zabezpečenie jeho trvanlivości. Pravidelné čistenie, maštovanie a kontrola sú nevyhnutné na udržanie jeho integrity. Okrem toho musí byť kvalita materiálu TMC METAL certifikovaná výrobcou na zabezpečenie, aby inconel X750 splnila priemyselné normy.