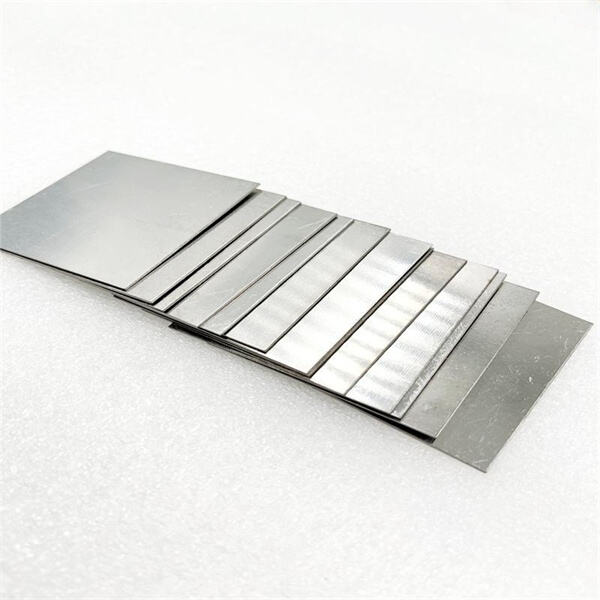

Niobium Foil: A Marvel of Modern Materials

Niobium foil is a type of metal foil that has become increasingly popular in recent years due to its many advantages. From TMC METAL Niobium foil flexibility to its high resistance to corrosion, this amazing material has revolutionized the way we approach many modern industries.

One of the key benefits of niobium foil is its high strength-to-weight ratio. This means that it is extremely lightweight yet incredibly strong, making it an ideal material for a variety of applications. In addition, TMC METAL niobium titanium is highly resistant to corrosion and can withstand extreme temperatures. This makes it perfect for use in harsh environments where other materials might fail.

Niobium foil is an innovative material that has been used in a variety of ways. It can be used in the aerospace industry to make lightweight aircraft parts, as well as in medical devices to make implants and other medical equipment. In addition, TMC METAL pure niobium can be used in nuclear reactors and particle accelerators, where it is essential to have a material that can withstand extreme conditions.

Niobium foil is also a very safe non-toxic material and biocompatible, making it ideal for medical applications. TMC METAL niobium bar is also non-magnetic, which means that it can be used in MRI machines without interfering with the imaging process.

Niobium foil is used in a variety of different applications, including:

- Aerospace industry: Niobium foil is used to create lightweight aircraft parts, such as wing struts and engine components.

- Medical industry: TMC METAL niobium wire is used to create implants, such as dental implants and orthopedic implants.

- Electronics industry: Niobium foil is used in electronic capacitors, which store energy and regulate voltage.

- Energy industry: Niobium foil is used in nuclear reactors, where it is used to help maintain critical reaction conditions.

Our company has over 26 years of experience in rare metal and non-ferrous metal processing as well as production. have developed many technical and R D personnel who have professional expertise to contribute the development of industry. also offer a supportive environment encourages growth our employees. We have experienced personnel can provide with after-sales service as well as support customer Niobium foil, provide technical support solve potential issues with quality. Collect and analyze customer feedback and take appropriate measures improve product quality and service quality.

Suzhou Tamuchuan, processing product Niobium foil in Suzhou manufacturing office area of 2,000 square meters, located there. primary products include rare metals, non-ferrous metals and various other types of metals. We have more than 2,000 partners have cooperation with world's top 500 companies. A specialized R D team available. Stable suppliers can be a fantastic support for large-scale productions, as well as top-of-the-line production equipment and instruments. We have highly skilled quality inspection team strictly control product quality. We have a good collaboration with our partners.

Our Niobium foil equipped with high-end manufacturing equipment as well as processing equipment, can perform high-end, custom metal processing, fine processing, and complex processing. We able process and produce metal components according to customer's specifications design drawings and can also be involved in product design and development We also offer OEM ODM services and have an R D facility that covers more than 500 square meters, professional R D personnel equipment that are able to collaborate on the development of products and tests as well as a range of processing equipment satisfy diverse customer requirements.

company has developed implemented stringent quality control process ensure that the products offer meet specified standards and specifications. We choose suppliers of high-quality ensure the ability trace and control quality of our supply chain runs from raw materials through to final products. have passed ISO9001 as well as SGS certifications that Niobium foil with industry and international standards. We develop quality management plans that include quality inspections, tests, and track and track manufacturing processes in accordance with rare metal and non-ferrous industry specifications.

When using niobium foil, it is important to handle it with care to avoid damaging the material. TMC METAL niobium and tantalum can be cut using a pair of scissors or a knife, but it is recommended that you use sharp, high-quality tools to avoid damage to the material.

Metals, we pride ourselves on providing high-quality niobium foil to our customers. Our TMC METAL niobium tantalum are subjected to rigorous quality control procedures to ensure that they meet the highest standards of performance and reliability.

Our niobium foil is made from high-quality, pure sourced niobium from trusted suppliers. We use advanced manufacturing techniques to produce our TMC METAL c103 niobium, ensuring that it meets the strictest quality standards.