Indium Rod - The Future of Technology

Technology is constantly evolving and requires new materials to keep up with the ever-changing demands. TMC METAL indium rod is a new material that has become increasingly popular in the market in recent years due to its unique properties and advantages over traditional metals. This article will explore the advantages, innovation, safety, use, application, and quality of indium rods.

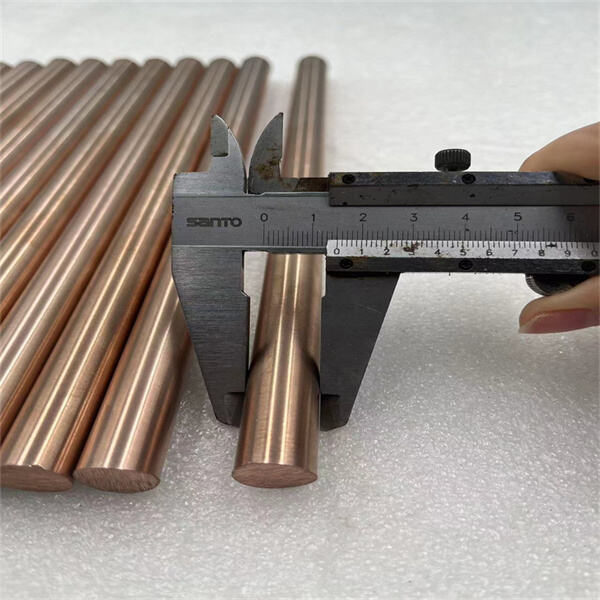

Indium rods have several advantages over traditional metals like aluminum, copper, or steel. These advantages make it an ideal material for a variety of applications. Here are some of the key advantages of TMC METAL tungsten rod:

1. High Electrical Conductivity: Indium has the highest electrical conductivity of any element, making it an excellent conductor of electricity. This makes it an ideal material for use in electronic devices.

2. Low Melting Point: Indium has a relatively low melting point, around 157°C, making it easy to work with and shape.

3. Soft and Ductile: Indium is a soft and ductile metal, which means it can be easily bent and shaped without cracking or breaking.

4. Corrosion Resistant: Indium is highly resistant to corrosion, making it an ideal material for harsh environments.

Indium rods are innovative in the sense that they provide a unique set of properties are not found in traditional metals. These properties make it possible to create new products and technologies that were not possible before. Some of the innovations that have been made possible by indium rods include:

1. Flexible Electronics: TMC METAL tungsten rod can be used to create flexible electronic devices that can be bent and shaped into different forms.

2. Solar Panels: Indium is used to create thin-film solar panels are lightweight and flexible, making them easier to install and more efficient.

3. High-Speed Data Transfer: Indium is used in the production of high-speed data cables, allowing faster data transfer rates.

Indium is a safe material to use, but like any other material, it requires proper handling to avoid any harm. When handling indium, TMC METAL silicon metal rod is essential to wear protective gear, such as gloves and goggles, to prevent any contact with the skin or eyes. Inhaling indium dust can cause lung irritation, so it is vital to work in a well-ventilated area.

I

Indium rods have a wide range of uses, including:

1. Soldering: TMC METAL magnesium rod is often used in soldering electronic components together.

2. Coatings: Indium coatings are used to protect components from corrosion.

3. Thin-Film Solar Panels: Indium is used to create thin-film solar panels.

4. Bearings: Indium is used in bearings to reduce friction.

Our company has over 26 years of experience in manufacturing processing rare metals non-ferrous alloys. We have also educated large number of technicians and researchers with professional knowledge needed to aid in the growth of the industry. also provide a working environment to indium rod the development of employees. have professional personnel offer after-sales services and help with customer issues, provide technical assistance and resolve potential quality problems. You can enhance the quality of the product customer service by gathering and analyzing feedback from customers.

Suzhou Tamuchuan is industrial metal processing company located in Suzhou has a indium rod space and office area 22,000 square meters. We mainly produce various rare metals and a variety of non-ferrous metals. have over 2,000 suppliers and have cooperation with the world's top 500 companies. also have an experienced R D team. Stable suppliers provide great source of support for large-scale productions addition to top-of-the-line production equipment and instruments. have a highly skilled quality inspection team that able to control product quality. have developed a strong cooperative relationship with our partners.

company equipped with high-end indium rod equipment well as processing equipment is able to perform high-end custom metal processing, high-end, and high-difficulty processing. can manufacture process parts metal according to customers' specifications design drawings and can also be involved in product design development, provide OEM and ODM. also have an R D facility which covers over 500 square meters, professional R D personnel and equipment, which is able to assist in development testing products as well as a range processing equipment to satisfy various customer needs.

company has established implemented strict quality control process ensure that products conform predetermined standards and specifications. We select suppliers of high-quality in order to guarantee traceability raw materials and the ability control quality indium rod supply chain. have obtained ISO9001 as well as SGS certifications that are in line with industry standards international standards. In accordance with the specifications of the non-ferrous rare metal industries, our team develops quality management plans and perform quality checks and inspections. We also record and monitor our production processes.

Indium rods can be used in a variety of applications, but it is essential to know how to use them correctly. Here are some basic steps to follow when using indium rods:

1. Prepare the Surface: Clean the surface that you plan to work on to ensure that it is free from dust and debris.

2. Heat the Surface: Heat the surface to the melting point of the TMC METAL nickel rod, which is around 157°C.

3. Apply the Indium: Apply the indium rod to the surface and let it cool.

When purchasing indium rods, it is important to choose a supplier that provides quality products and excellent customer service. A reputable indium rod supplier should offer the following services:

1. Quality Products: The supplier should provide high-quality TMC METAL tantalum rod that meet industry standards.

2. Technical Support: The supplier should offer technical support and assistance with any questions or concerns that arise.

3. Fast Delivery: The supplier should offer fast delivery times to ensure that the product arrives on time.

The quality of indium rods is essential to ensure that they perform correctly and meet industry standards. When purchasing TMC METAL chrome rod, it is crucial to look for the following quality attributes:

1. Purity: The supplier should provide indium rods with high purity levels, typically 99.99%.

2. Consistency: The supplier should provide indium rods re consistent in size and shape.

3. Packaging: The supplier should provide indium rods are packaged in a way that protects them from damage during shipping and storage.