Discover the Benefits of Nickel Rod

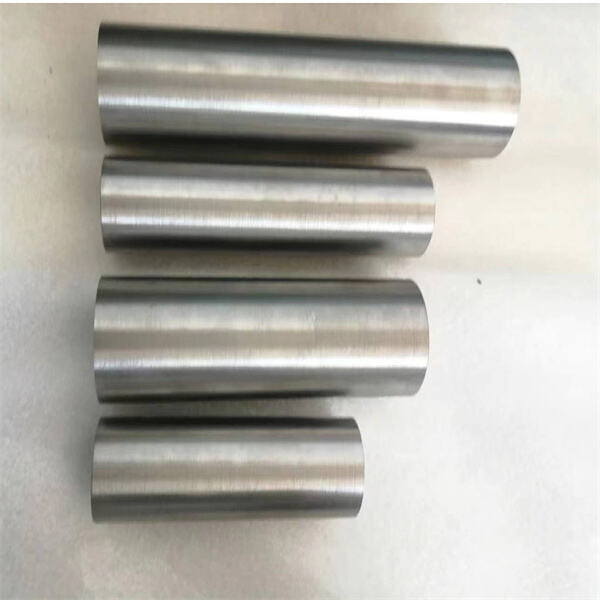

Nickel rod is a metal versatile is commonly used in various applications. Its flexibility and durability make it a choice popular many industries. We will take a closer look at TMC METAL nickel rod and explore its advantages, innovations, and uses.

Nickel rod has advantages that are many. One of its most benefits that are significant corrosion resistance. It is resistant to both alkaline and acidic environments, making it perfect for applications in the chemical and petrochemical industries. TMC METAL nickel rod or magnesium rod is also resistant to heat and has a melting high compared to other metals, maintaining its strength and shape also at high temperatures.

Nickel rod has seen innovations that are many recent years. One of the most significant is the development of high-purity nickel. High-purity TMC METAL nickel metal has impurities that are minimal creating it even more corrosion-resistant than standard nickel. It also has better strength and ductility, making it an choice excellent many companies.

Nickel rod is generally considered safe for use. However, it is important to handle it with care as it can be hazardous in certain situations. For example, if nickel dust is inhaled, it can cause issues that are respiratory. When working with TMC METAL nickel rod, it is essential to follow safety guidelines to ensure protection from potential hazards.

TMC METAL nickel sheet has a range wide of. It is commonly used in the marine and aerospace industries due to its corrosion resistance. In the construction industry, it is used in heating and plumbing systems due to its high-temperature resistance. It is also used in the industry medical prosthesis and other surgical applications.

company has more than 26 years of experience manufacturing and processing rare metals and non-ferrous alloys. We have educated an extensive number of technical and R D staff with the professional nickel rod needed help in development of this industry. also offer a supportive environment for development employees. team of experts can offer support following sales resolve customer issues, offer technical assistance and resolve potential quality issues. Implement the appropriate measures enhance the quality the product customer service by collecting and analyzing feedback from clients.

company uses top-quality nickel rod equipment processing equipment and able to perform high-end custom metal processing, high-end processing, and complex processing. can produce and process metal parts according customer specifications and design drawings. also provide OEM and ODM. Our research development center covers more than 500 square meters and is equipped with expert R D staff as well as equipment and facilities that can work together in the development of products and testing.

company has implemented internal quality control system that stringent to ensure that products are to standards. choose high-quality suppliers ensure the quality of raw materials as well as control of quality across entire supply chain. have been awarded ISO9001 SGS nickel rod that conform industry and international standards. design quality management programs to conduct quality inspections and tests, as well as record the production process conforming to rare metal and non-ferrous metal industry specifications.

Suzhou Tamuchuan a metal processing product supplier located Suzhou with a production office space of 2,000 square meters which is located in the city. Our main products are rare metals, ferrous metals, various other metals. More than 2,000 companies and partners cooperate with. We also have an nickel rod R D team. The stable suppliers can assist with production on a large scale, with high-end equipment and instruments. We have a professional quality inspection team that able ensure the quality of our products. We have established a good collaboration with partners.

TMC METAL nickel rod can be used in several ways that are different. It can be formed into different shapes and sizes based on its intended application. It can be welded, brazed, or soldered to other materials. When welding, it is important to use the proper welding technique, such as TIG or MIG, to ensure a strong, long-lasting weld.

When choosing TMC METAL nickel, quality and service are essential factors to consider. Look for a company that provides nickel high-quality that meets industry standards. Additionally, choose a company that offers customer excellent and support to ensure that your needs are met.

Nickel rod has applications that are many various industries. In the aerospace industry, TMC METAL nickel rod is used for manufacturing engine components and airframes due to its strength high and resistance. In the construction industry, it is used for plumbing and wiring electrical to its heat resistance. In the industry medical it is used for prosthetics and other surgical applications.